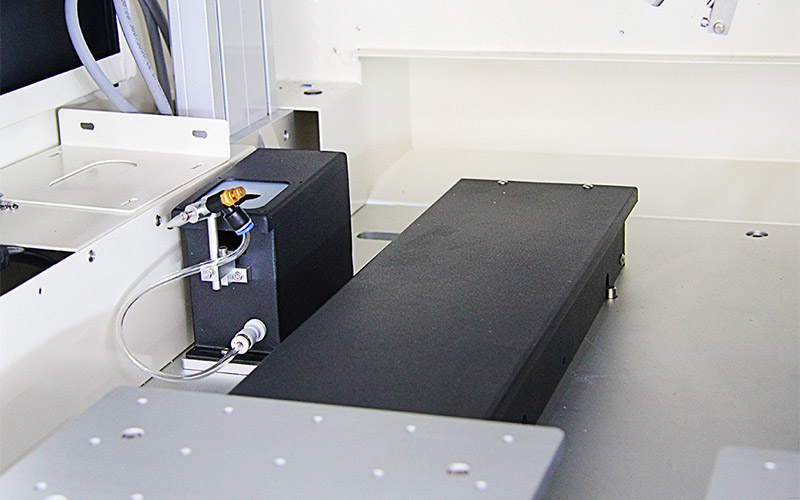

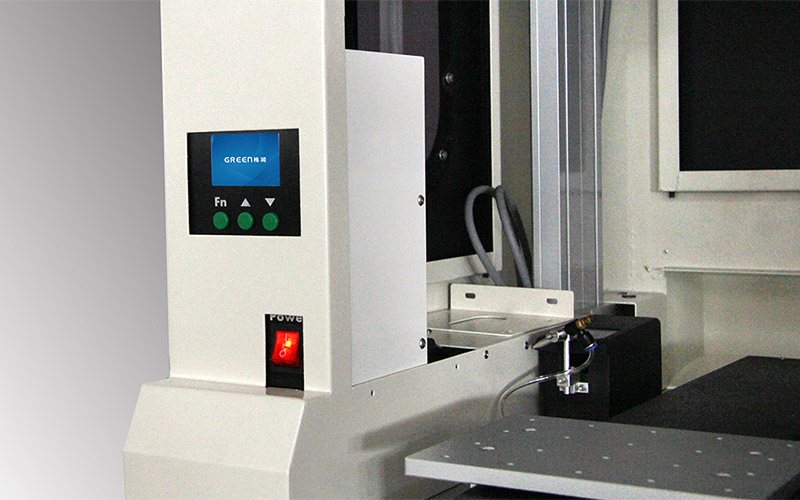

PC Type Automatic Laser Soldering Machine

Specifications

|

Brand Name |

GREEN |

|

Model |

SI10DR |

|

Product Name |

Laser Soldering Machine |

|

Platform Itinerary |

X=500mm, Y1=300mm, Y2=300mm, Z=100mm,R=360° |

|

Z-axis Load |

3KG |

|

Outer Demension |

800*860*1520mm |

|

Dive Mode |

AC220V 10A 50-60HZ |

|

Type |

Soldering Machine |

|

Weight (KG) |

170 KG |

|

Key Selling Points |

Automatic |

|

Place of Origin |

China |

|

Warranty of core components |

1 Year |

|

Warranty |

1 Year |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Showroom Location |

None |

|

Marketing Type |

Ordinary Product |

|

Condition |

New |

|

Core Components |

Stepping motor, Synchronous belt, Precision Guide Rail, Temperature controller |

|

Applicable Industries |

Machinery Repair Shops, Manufacturing Plant, Other, Communication Industry, 3C Consumer Electronics Industry, Automobile Industry, New Energy Industry, LED Industry, Electronics Industry |

Feature

GREEN SI10DR PC Type Soldering Machine

1. The user software developed based on the Windows operating system is more in line with the user's operating habits;

2. High-definition touch screen man-machine interface, real-time welding monitoring of running track;

3. It has the function of automatic detection of tin deficiency and tin blocking, and directly protects the welding products;

4. Can be connected to MES system.

Product introduction

Measured fully automatic programmer / fully automatic writer / fully automatic writer most powerful symbol: Output rate, also known as UPH, that can produce the number of chips per hour.

Output rate is determined by the mechanical arm travel time, writing time, the number of modules; their relationship is: When the chip burning time is small, the mechanical arm stroke cycle is fast, and a certain percentage of the module number, Only unified coordination can have an impact on production capacity;

After testing, high-speed arm with an efficient programmer, when deploy four modules,the production capacity of robot reach the peak.Every module is fully loaded operation, if the module configuration too much, the arm crawling the cycle has reached the limit, which can not increase productivity, Instead, more configuration modules led to a corresponding increase in costs. Therefore, the module is not as good as possible.

Technology Center

Benefit from our expertise and many years of experience. Develop the optimum process for your requirements together with us. We are specialists for different applications and processes.

Experience & know-how

Our process experts are in close contact with material manufacturers and have many years of experience in process development and processing, even with challenging materials.

Procedure of a trial in our Technology Center

In order to optimally prepare a process trial, we need the material to be processed, for example an impregnating resin, a thermally conductive material, an adhesive system or a reactive casting resin, in sufficient quantity with the corresponding processing instructions. Depending on how far advanced the product development is, we work in our application trials with prototypes up to original components.

For the trial day, specific targets are set, which our qualified personnel prepare and carry out in a structured, professional manner. Afterwards, our customers receive a comprehensive test report in which all tested parameters are listed. The results are also documented in pictures and audio. Our Technology Center staff will support you in defining the process parameters and make recommendations.

Benefits

- Guidance on component optimization for series production

- Determination of the process parameters with series equipment

- Summary of the results in a comprehensive test report

- Ideal basis for decisions

Sample production

Within the scope of process development, we produce A, B and C samples for our customers. This way, high investment costs can be prevented, especially in the introduction phase of a new production stage. With our in-house machine technology, we produce parts as prototypes, functional samples or pre-series samples at low cost. Benefit from short delivery times and high quality directly from the equipment manufacturer.