We will provide product documentation and quotations per your request.

Application in New Energy Industry

GREEN is a National High-Tech Enterprise dedicated to R&D and manufacturing of automated electronics assembly and semiconductor packaging & testing equipment. Serving industry leaders such as BYD, Foxconn, TDK, SMIC,Canadian Solar, Midea, and 20+ other Fortune Global 500 enterprises. Your trusted partner for advanced manufacturing solutions.

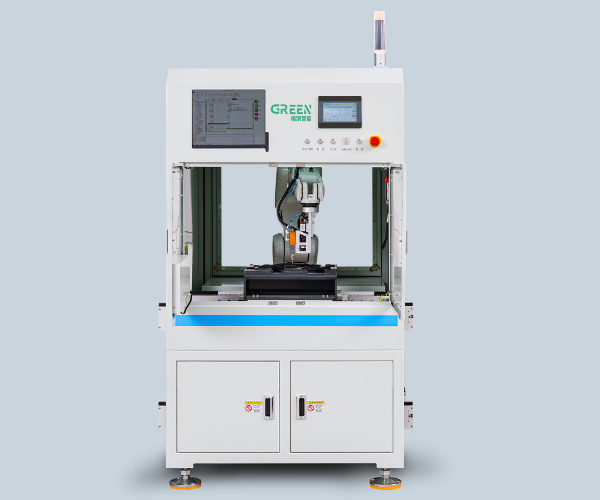

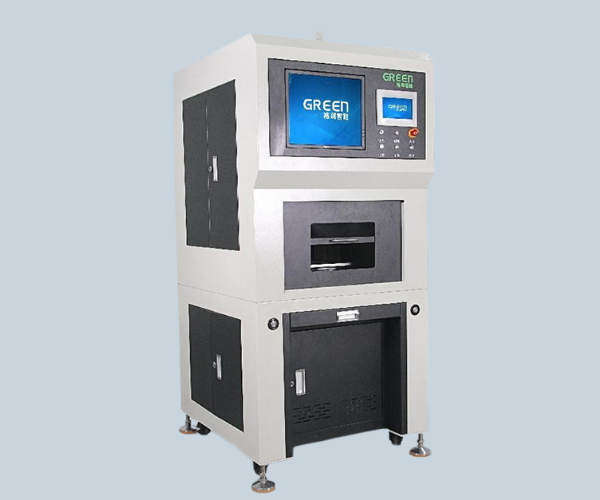

In the new energy industry, five core technologies – precise adhesive dispensing, soldering, screw fastening, automated optical inspection (AOI), and wire bonding – form the backbone of manufacturing excellence across battery packs, solar panels, and electric vehicle components. These processes directly enable critical outcomes: Safety through leak-proof battery sealing and reliable high-power connections; Efficiency via automated precision that minimizes production waste; and Durability via robust bonds and fastenings capable of withstanding extreme environments like EV vibrations and outdoor solar exposure.

Collectively, these technologies drive the scalability and reliability of clean energy solutions – from gigafactories producing next-generation batteries to smart grid infrastructure – underpinning the sector's rapid global expansion while ensuring end-product performance and safety standards are met.

WHAT IS YOUR INDUSTRY?

New Energy Vehicle Manufacturing

IGBT Modules: Utilize two-component screw-valve dispensing for precise mixing ratio control, guaranteeing insulation and thermal performance.

Battery Packs: Apply vacuum potting technology for sealing, meeting industrial-grade protection standards for moisture resistance and shockproofing.

Photovoltaic Manufacturing

Double-sided modules and heterojunction (HJT) cells require dynamic glue width control and compatibility with high-weather-resistant materials (e.g., silicone/epoxy resin) to ensure long-term sealing integrity. Inline vision-guided dispensing systems achieve precision filling for curved modules and micro-gaps.

Energy Storage Equipment

Thermal conductive adhesives enable high-speed filling of energy storage cabinet structures, adapting to extreme temperature cycling conditions while significantly enhancing system reliability.

New Energy Vehicle Electronics

IGBT Precision Soldering: Laser soldering technology significantly reduces thermal input, preventing damage to power modules while achieving ultra-high precision connections.

Dissimilar Metal Welding:Overcomes compatibility challenges in copper-aluminum joints, enabling ultra-thin solder points (<0.3mm) for lightweight electrical interconnects.

Photovoltaic Systems

Miniature Power Electronics: Adapts to micro-pitch soldering requirements on high-density PCBs, replacing conventional processes with automated production line solutions.

Energy Storage Equipment

Energy Storage Device Manufacturing: Addresses high-reliability interconnection challenges between battery modules and power components, ensuring long-term operational stability.

We will provide product documentation and quotations per your request.