multi-function high speed Fully multi function automatic dispensing machines

Specifications

|

Brand Name |

GREEN |

|

Model |

GR-FD03 |

|

Product Name |

Dispensing Machine |

|

Lock Range |

X=500, Y=500, Z=100mm |

|

Power |

3KW |

|

Repeatability Accuracy |

±0.02mm |

|

Dive Mode |

AC220V 50HZ |

|

Outer Demension(L*W*H) |

980*1050*1720mm |

|

Key Selling Points |

Automatic |

|

Place of Origin |

China |

|

Warranty of core components |

1 Year |

|

Warranty |

1 Year |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Showroom Location |

None |

|

Marketing Type |

Ordinary Product |

|

Condition |

New |

|

Core Components |

CCD, Servo motor, Grinding screw, Precision guide rail |

|

Applicable Industries |

Manufacturing Plant, Other, Communications Industry, LED Industry, Electronics Industry, 5G, Electronic Industry |

Feature

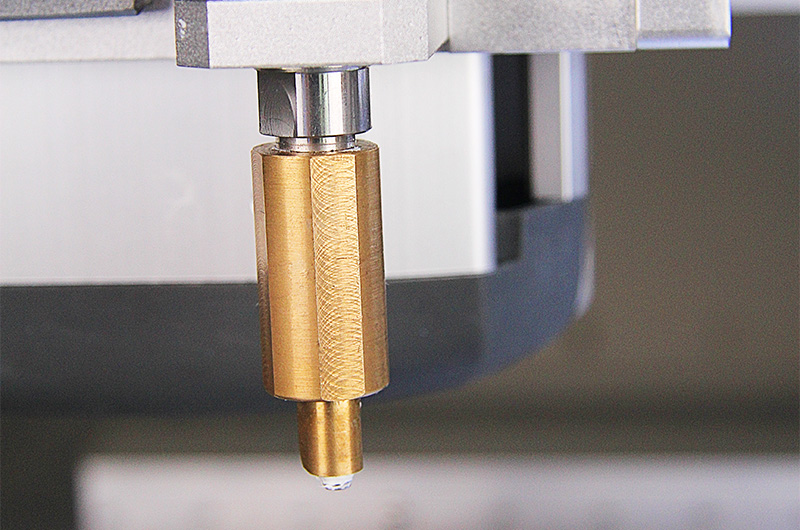

- Speed:UV glue and some dilute silica gel can achieve a circle of 18 diameters in 1 second

- Map function,saving debugging time

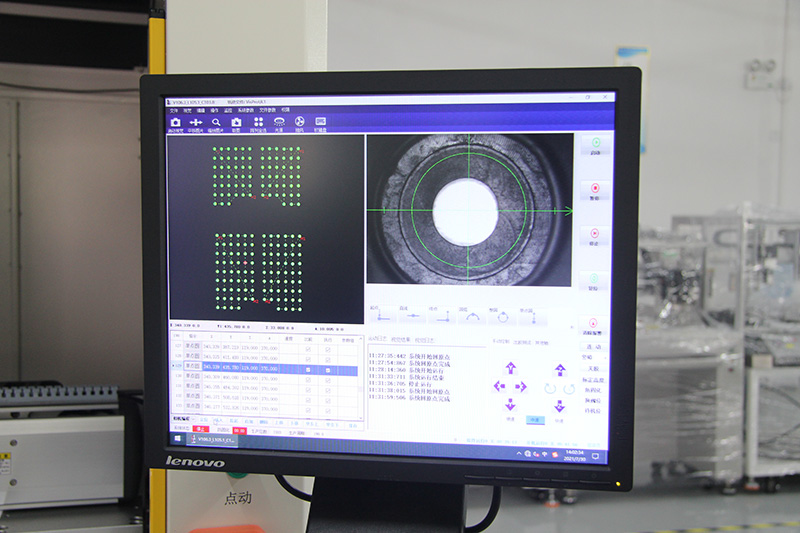

- CCD:Recognize mark points,accurately edit the dispensing path,and accurately align

- Strong versatility,which can satisfy 90% of fixed PACK batteries

Application Range of GREEN MSL800 Floor type Dispensing Machine

mobile phone buttons, printing, switches, connectors, computers, digital products, digital cameras, MP3 ,MP4, electronic toys, speakers, buzzers, electronic components, integrated circuits, circuit boards, LCD screens, Relays, crystal components, LED lights, chassis bonding, optical lenses, mechanical parts sealing

Our fully automatic machines are suitable for fully automatic series production for various dispensing applications. Automation concepts such as rotary indexing tables, sliding carriage or integrated conveyor belts are available. The fully automatic machine solutions are available in different sizes and working ranges.

They can be used for processing 1C, static or dynamic dispensing materials to be mixed. All components for process monitoring and standardized interfaces are available.

Dispensing Methods

Bonding

Adhesive bonding is a dispensing process used to join two or more parts together. Adhesive bonding processes are becoming increasingly established as a field of application in dispensing technology.

Through the dispensing method bonding, two or more joining partners are joined together. Effective bonding enables a material-to-material bond without introducing heat and causing possible damage to components. Ideally, in the case of plastic parts, activation of the surface takes place by means of atmospheric or low-pressure plasma. During application, the surface and material remain unchanged. Bonding therefore does not affect factors of the component such as mechanics, aerodynamics or aesthetics.

As a rule, the process consists of two steps: First, the adhesive is applied and then the parts are joined. In this process, the adhesive is applied to defined areas on the outside or inside of the component. Crosslinking of the adhesive takes place through material-specific properties. In addition to a variety of industrial sectors such as medical technology, electronics production, lightweight construction, this dispensing process is frequently used in the automotive sector. Adhesive bonding is used, for example, in electronic control units, LiDAR sensors, cameras and many more.

Sealing

The dispensing method sealing is an effective process of protecting components from external influences by creating a barrier.

Sealing is an effective dispensing method for protecting components from external influences by means of a barrier. A usually highly viscous sealing material is applied to the components according to a specified two-dimensional or three-dimensional sealing contour. The most common applications here are the sealing of housings and housing covers. In addition, this method is used to join components together. It is used to eliminate dust, temperature-related influences, moisture, protection of sensitive components and other external influences. In order to achieve the optimum sealing contour, a continuous, precise dispensing application is essential. The dispensing technology of “Green Intelligent” is flexibly designed for the respective required application and the dispensing material.

Potting and vacuum potting

Optimal protection for electronic components is provided by the dispensing process of potting under atmosphere or under vacuum.

The potting of components is chosen to protect sensitive components, eliminate dust, temperature-related influences, moisture or increase service life. The encapsulation of electronics is also one of the applications of this dispensing process. Components are filled or poured with low-viscosity potting materials such as polyurethanes (PU), epoxy resins (epoxy), silicones.

The material preparation should be selected ideally for the potting medium and according to the application.

Typical applications are pacemakers, cable bushings, sensors or electronic components.

Technology Center

Benefit from our expertise and many years of experience. Develop the optimum process for your requirements together with us. We are specialists for different applications and processes.

Experience & know-how

Our process experts are in close contact with material manufacturers and have many years of experience in process development and processing, even with challenging materials.

Procedure of a trial in our Technology Center

In order to optimally prepare a process trial, we need the material to be processed, for example an impregnating resin, a thermally conductive material, an adhesive system or a reactive casting resin, in sufficient quantity with the corresponding processing instructions. Depending on how far advanced the product development is, we work in our application trials with prototypes up to original components.

For the trial day, specific targets are set, which our qualified personnel prepare and carry out in a structured, professional manner. Afterwards, our customers receive a comprehensive test report in which all tested parameters are listed. The results are also documented in pictures and audio. Our Technology Center staff will support you in defining the process parameters and make recommendations.