Industrial Automatic Rotating Dispenser 4 axis glue dispenser machine DP500D

Device Parameter

| Model | DP500D |

| Spray speed | 200 points/sec. |

| Min.point diameter | 0.2mm(depending on glue) |

| Optimal viscosity range | 5000-200000cps |

| Min. dispensing volume | 5nl |

| Min. drive air pressure | 0.5MPa |

| Setting method | Handheld programmer |

| Max. operating frequency | 250 cycles/s |

| Drawable graph | Straight line/circle/arc/continuous dash/3D/irregular graph |

| Program capacity | 150 files(1900 dispensing points/ file) |

| Power supply | AC220V 10A 50-60HZ |

| Max. power | 350W |

| Input air pressure | 0.4-0.7Mpa |

Working range |

DP500D(500*300*300*100);DP600D(600*400*400*100);DP300(300*300*100) ; DPI400(400*300*300);DP500(500*500*100); |

| Weight | 220kg |

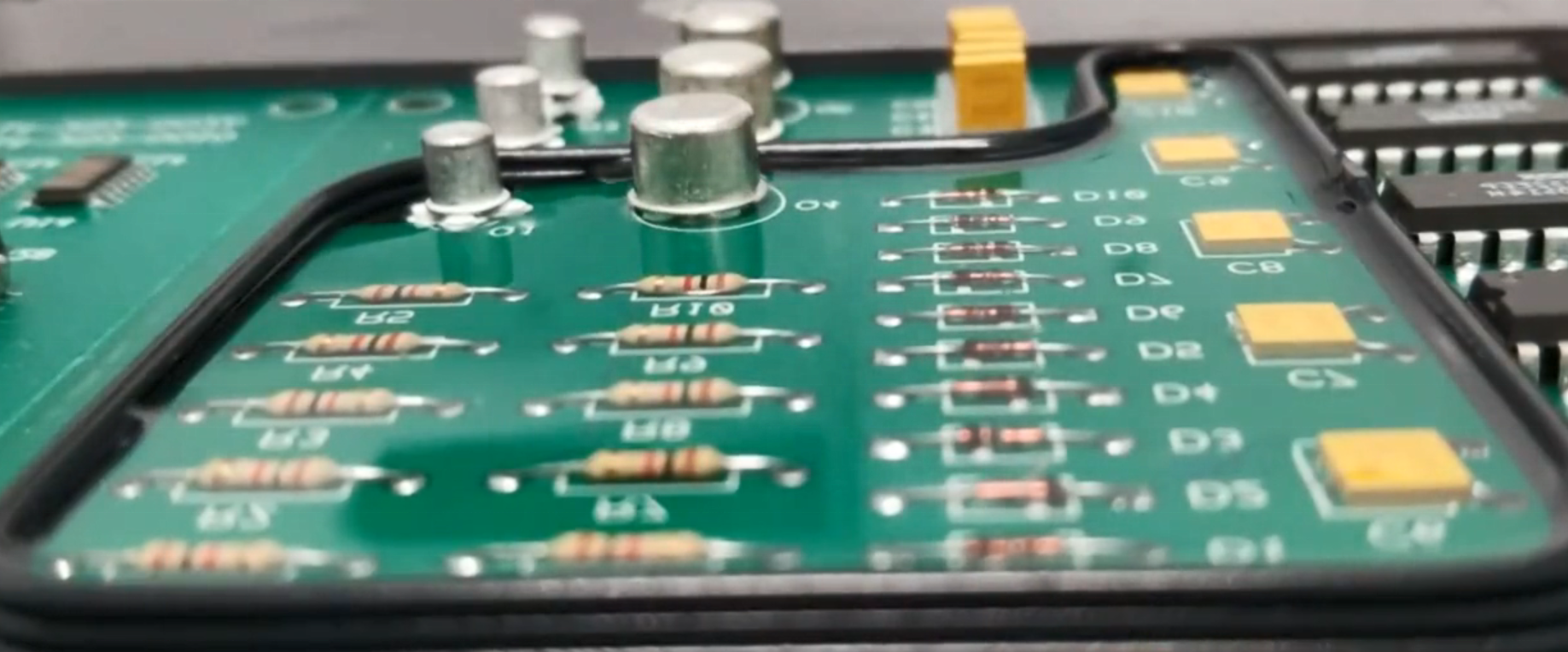

Device features

1. New sheet metal design and profiles are adopted, and the overall weight of the machine is reinforced,high-speed running, no Jitter;

2. Improved arrangement of original structural units, convenient disassembly,easy to for maintenance and inspection and replacement of parts;

3. Simple maintenance, it is also easy for newcomers to learn;

4. Cost-effective, no price increase for material replacement, but higher quality.

Principle of dispensing machine

1. Principle: The dispensing machine sends compressed air into the rubber bottle (syringe) to press the rubber into the feed tube connected to the piston chamber. When the piston is on the up stroke, the piston chamber is filled with rubber. When the piston pushes the rubber dripping needle downward, the rubber is pressed out of the needle nozzle. The amount of glue dripped is determined by the downward stroke distance of the piston, which can be adjusted manually or controlled in software.

2. Features: High speed, low sensitivity to glue viscosity.

3. Advantages: It can improve dispensing speed, dispensing environment and dispensing quality..