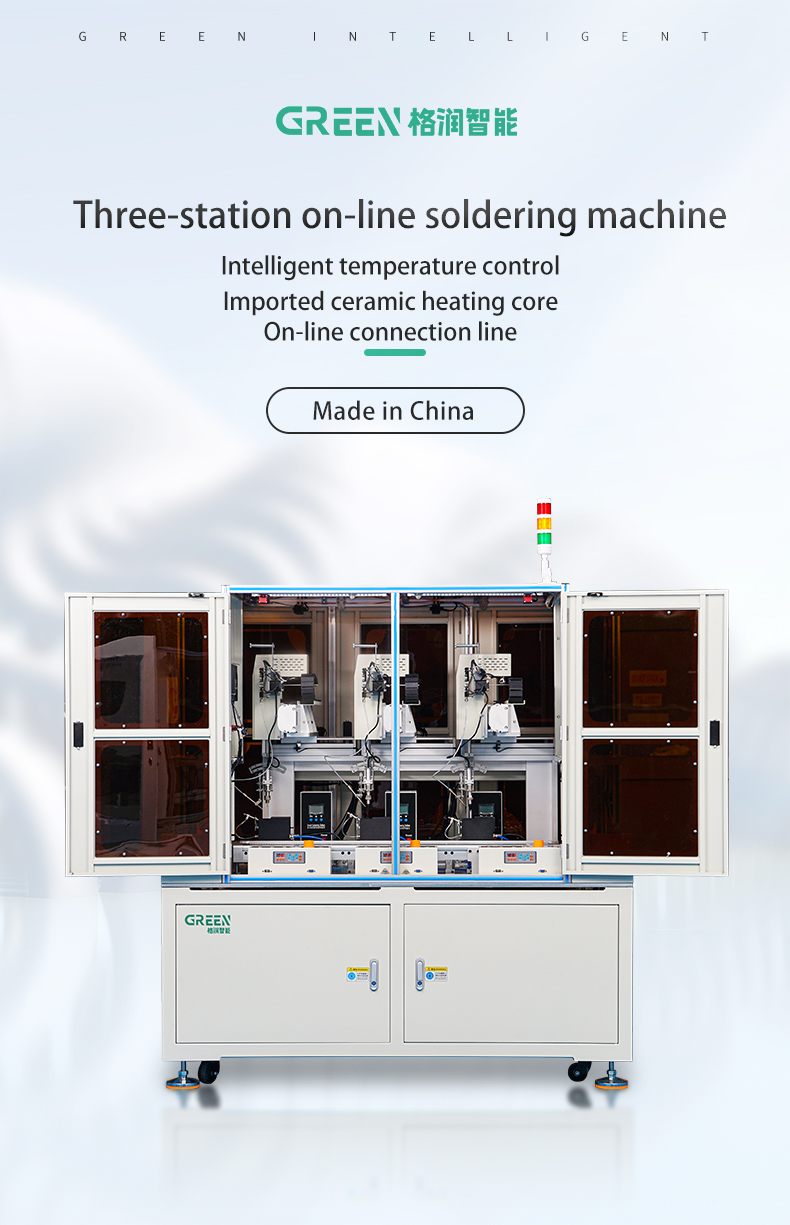

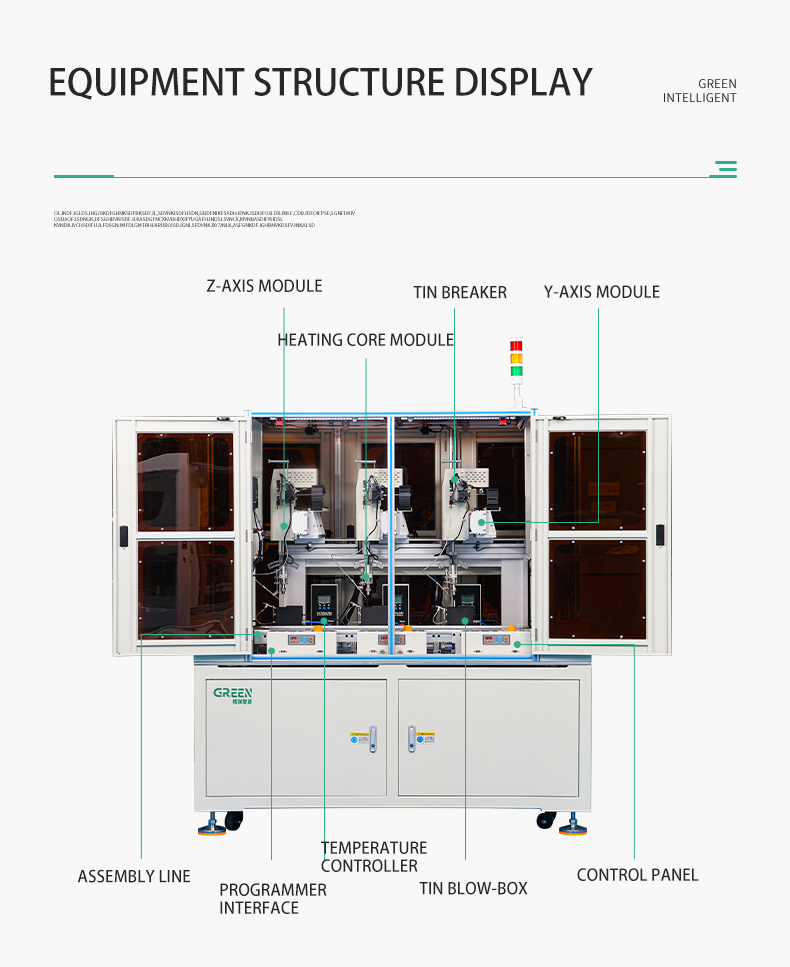

High Production Efficiency Green Automatic Three-station On-line Soldering Machines

Device Parameter

|

Model |

GR-OH05 |

|

Key Selling Points |

Automatic |

|

Weight (KG) |

1200 KG |

|

Type |

Soldering Machine |

|

Brand Name |

Green |

|

Rated Duty Cycle |

24 Hour Continually |

|

Rated Capacity |

Option |

|

Voltage |

220V |

|

Current |

50HZ |

|

Dimensions |

L1700mm*W900mm*H1835mm |

|

Use |

PCB |

|

Solder stroke |

100*200*100(unit: mm) |

|

Velocity of motion |

XY axis (0~ 800mm,s) Z axis (0~300mm,s) |

|

Repeatability |

±0.02 mm |

|

load |

0.4~0.7MPa |

|

Program capacity |

Conveying line load 10KG |

|

Temperature controller |

150W,200W,400W optional |

|

Temperature range |

0~450℃ |

|

Alarm temperature range |

Alarm temperature range |

|

Heating time |

0~9.9s |

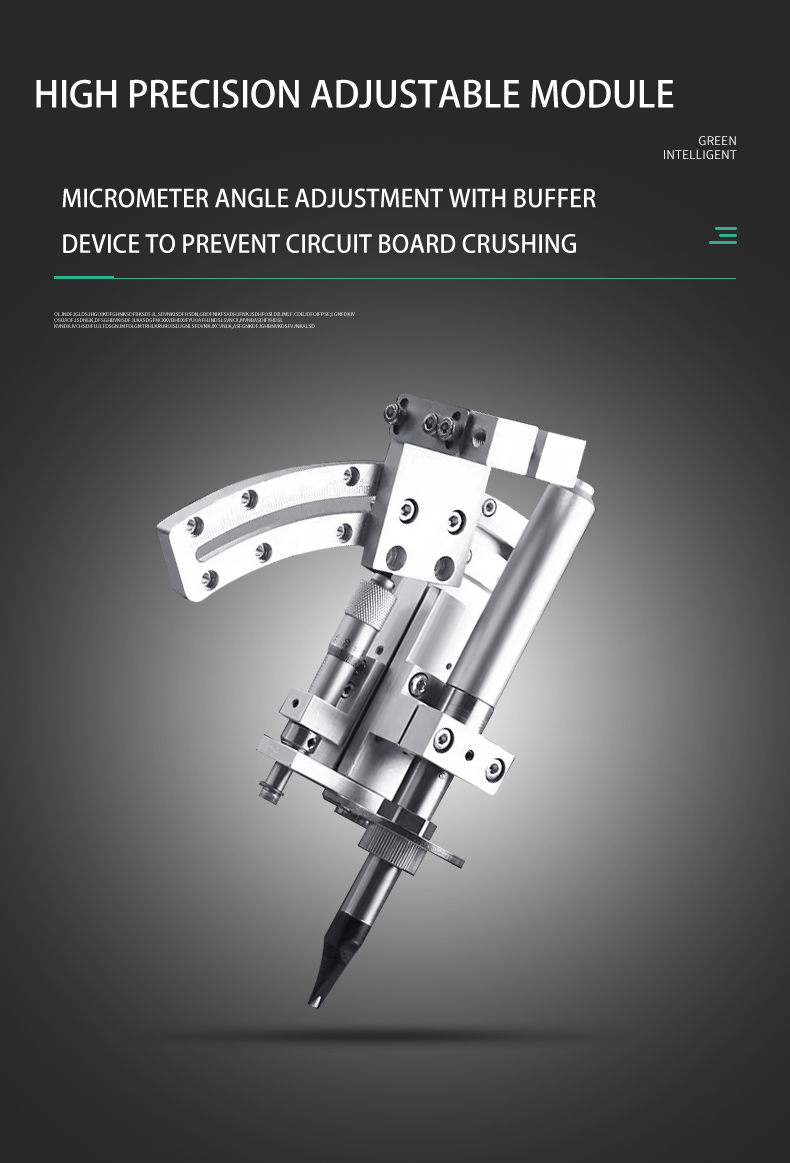

Device features

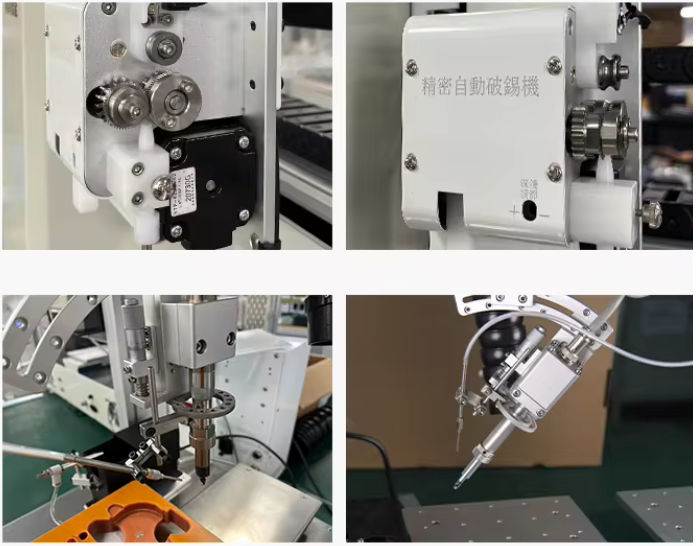

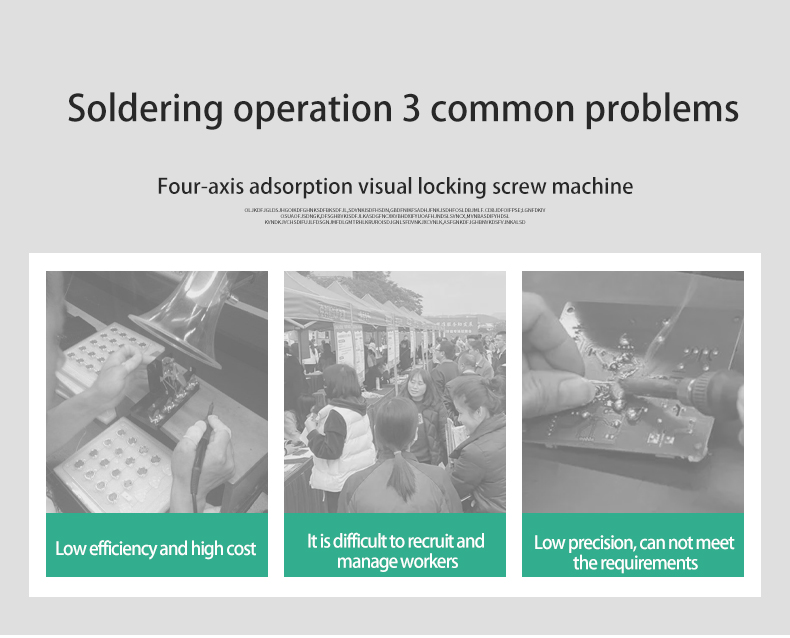

1.Flexible soldering methods, with spot welding, drag welding (pull welding) and other functions

2.The device can store 150 processing files, 1500 programming points per group

3.Solder jitter function, opening this function when welding can make welding faster, especially effective for large solder joints

4. The solder joint track is visible, so that the operator can understand the solder progress and the engineering personnel can debug it easily

5. The device writing work program can be copied from point to point and block to block, shortening the program writing time and easy to learn

6. The equipment has automatic cleaning function, which effectively guarantees the solder processing quality and prolonging the service life of the soldering iron tip

7. Precision stepping motor drive and advanced motion control algorithm are adopted to effectively improve motion positioning accuracy and repetition accuracy

8. Double-station alternating work, one side is welding work, the other side can be placed products, effectively improve production efficiency

Application Range

Mobile phone, computer, integrated circuit, tablet, digital automotive industry, battery assembly, loudspeaker, PCB board, semiconductor microelectronics assembly, camera module soldering.

Packing & Delivery