High Precision Green Soldering Machines Automatic System Duplex Laser Solder Ball Welding Machine

Device Parameter

| tem | value |

| Type | Soldering Machine |

| Condition | New |

| Applicable Industries | fuse industry, semiconductor industry, communication industry |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1.5 Years |

| Core Components | PLC, Motor, Pressure vessel |

| Showroom Location | None |

| Place of Origin | China |

| Guangdong | |

| Brand Name | GREEN |

| Voltage | 220V |

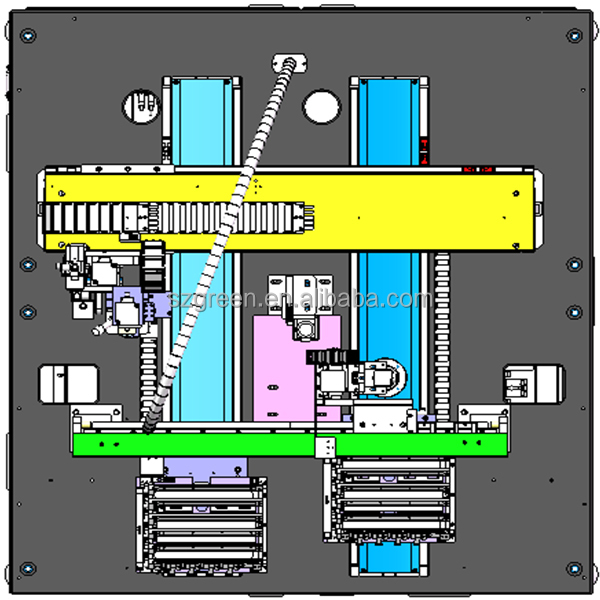

| Dimensions | 100*110*165(cm) |

| Usage | soldering wire |

| Warranty | 3Years |

| Key Selling Points | High-accuracy |

| Weight (KG) | 500KG |

| Model | LAB201 |

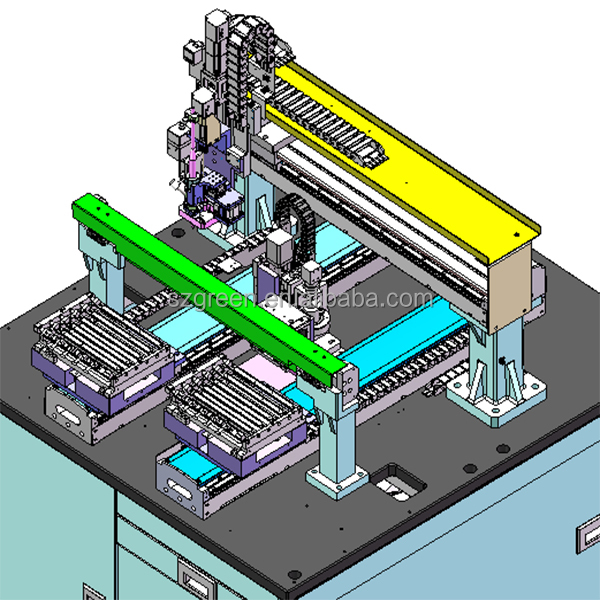

| Solder ball specifications | 0.15-0.25mm/0.3-0.76mm/0.9-2.0mm(Optional) |

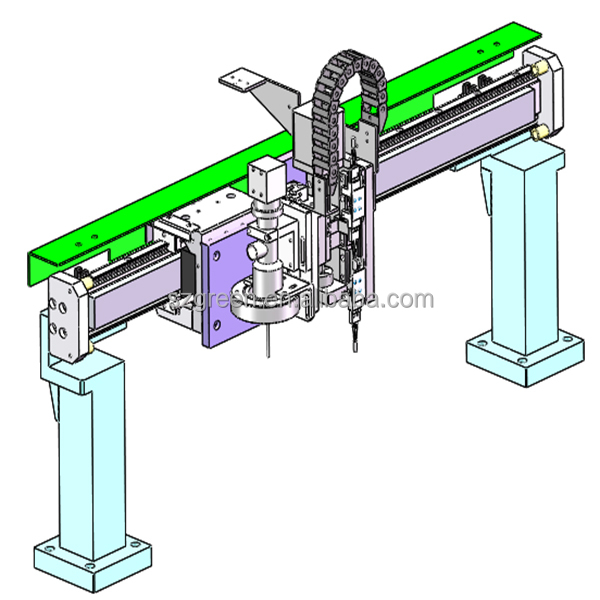

| Visual positioning system | CCD, The resolution±5um |

| Camera pixels | 5 million pixels |

| Control mode | PLC+PC Control |

| Mechanical repeatability accuracy | ±0.02mm |

| Processing range | 200mm*150mm(Customizable) |

| Use power | <2KW/H |

| Air source | Compressed air>0.5 MPa nitrogen>0.5MPa |

| Outer demension(LW*H) | 1000*1100*1650(mm) |

Device features

1. The heating and droplet process is fast and can be completed within 0.2s;

2. Complete the melting of the solder ball in the solder nozzle without splashing;

3. no flux, no pollution, to maximize the life of electronic devices;

4. The minimum diameter of the solder ball is 0.15mm, which is in line with the development trendof integration and precision;

5. Welding of different solder joints can be completed through the selection of solder ball size;

6. Stable welding quality and high yield rate;

7. Cooperate with CCD positioning system to meet the needs of assembly line mass production;

8. UPH > 8000 points, yield > 99% (different according to different product )

Application field

CCM camera/module, gold finger/FPC, wire, communication device, optical device, fuse industry,semiconductor industry solder

Application Range

Laser solder ball welding realizes precision class: PCB pad and gold finger solder connection, FPC and PCB welding, wire rod and

PCB welding, part THT plug-in device soldering. Products with PIN pins on one side and contralate products with PIN pins on both

sides, and many other precision welding products.

Packing & Delivery