Green Tabletop Automatic fixing Screw Machine Shoulder-to-Shoulder Screw Machines

Device Parameter

| Model | GR-DL06 |

| Weight (KG) | 400 |

| Brand Name | GREEN |

| Video outgoing-inspection | Provided |

| Size(L*W*H) | 860*603*710MM |

| Applicable Industries | Mobile phones, electronic industry, automatic industry, camera module |

| Power | 1.2KW |

| power supply | 0AC220V,50HZ |

| Lock one screw for time | Approx1-15 sec |

| Applicable screws | M1-M6.0 |

| Alarm function | Floating locks,slippery teeth,leaky locks |

| Display mode | LED teaching box |

| I,O signals | 12In puts,12 Out puts |

| Program recording mode | 99 groups |

| Motor type | Stepper motor |

Device features

1. The equipment adopts shoulder-to-shoulder double Z-axis design, one can top two machines, the equipment has strong versatility, small size, can cooperate with production line operations, and is convenient to replace products.

2. The device can store 99 operating programs.

3. High degree of automation and simple operation.

4. Vacuum-suction automatic crew machine, very suitable for smaller screws. There is no requirement for the length-to-diameter ratio of the screw.

5. The equipment adopts double Y axis and double Z axis design, and the equipment can lock the screws of two identical products at the same time, reducing labor intensity and improving production efficiency

6. When the device support fails, select the replay or skip mode.

7. The equipment writing work program can carry out point-to-point, block-to-block copying, with regional array copying, platform copying, batch editing, single-step operation, etc. Features, shorten programming time, and easy to learn.

8. After the action parameters are edited, the action parameters are downloaded to the controller through the serial port,which can be run independently offline, or the action parameters can be saved to the handheld box.Easy to call.

9. The equipment adopts precision stepper motor drive and advanced motion control algorithm to effectively improve the accuracy of motion positioning and repeatability.

10. Easy torque adjustment to ensure locking quality.

11. The equipment is equipped with servo electric batch, servo electric batch has high-precision torque control, torque accuracy reaches 土3%-=5%, servo electric batch supports a variety of tightening tasks,Each task supports multiple tightening steps.

12. The equipment is equipped with safety protection grating to effectively protect the safety of operators.

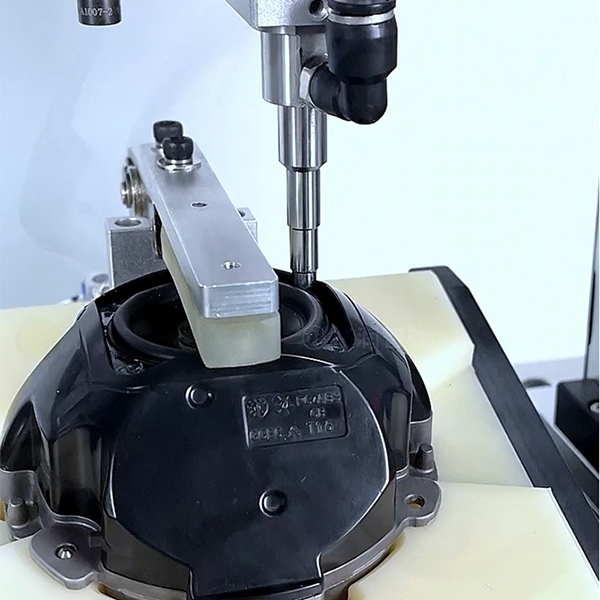

Details