Green on-line DP1010 black/red glue silver /solder paste dispensing machine

Device Parameter

| Model | DP1010 |

| Transport height | 900±20mm |

| Transport range | 50-300mm |

| Transport direction | L→R(R→L Optional) |

| Dispense Valve | Non contact piezoelectric injection valve |

| Valve pressure stabilizing device | Electronic communication synchronous pressure stabilizing device |

| Load | 8kg |

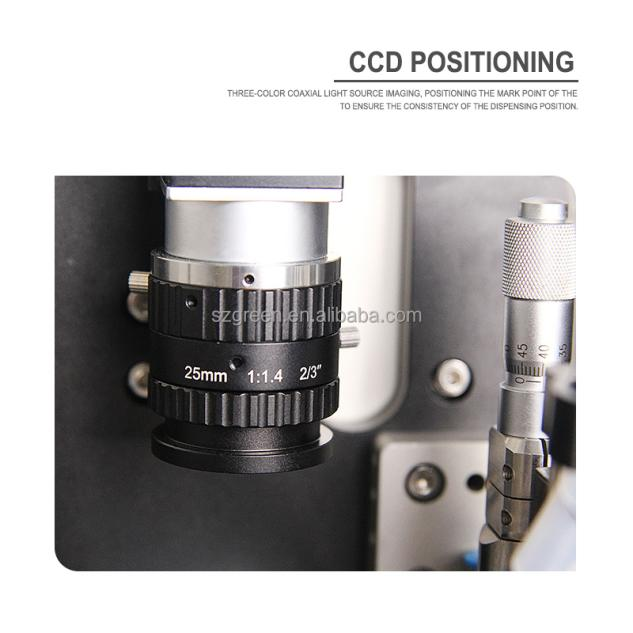

| CCD Visual Possitioning System | 130W Camera+Tri-color coaxial light source |

| High speed dispensing valve | Ceramic valve,screw valve, two-component AB valv |

| Laser Height Measurement | Adjustbale |

| keywords | gluing machines |

| Weighing system | Accuracy of microbalance: 0.01mg, 0.1mg |

| PCB size | 500*500 (Customized) |

| Outer demension(L*W*H) | L1040*W1015*H1510mm (Excluding tricolor lights, monitor and keyboard) |

| Weight | 850kg |

| Pressure | 0.6Mpa |

| Air consumption | 40 L/min |

| Power supply | AC:220V,50~60HZ |

| Power | 2.5KW |

Device features

1. Cost-effective, non-contact jet valve under high performance conditions, enabling smaller dispensing diameter and wider application field jet valve.

2. The minimum overflow width is only 0.2mm (related to configuration and glue)

3. CCD identification system, identify MARK points, more accurate alignment, identity recognition, automatic program adjustment, foolproof, data statistics and other functions to achieve intelligent manufacturing.

4. Support three-axis space linear interpolation, arc interpolation, ellipse interpolation, irregular curve, continuous interpolation input program and other functions can be three-dimensional dispensing.

5. Dispensing force automatic compensation function.

6. Precise selection, precise control of electronic equipment, improve production efficiency and

improve product quality

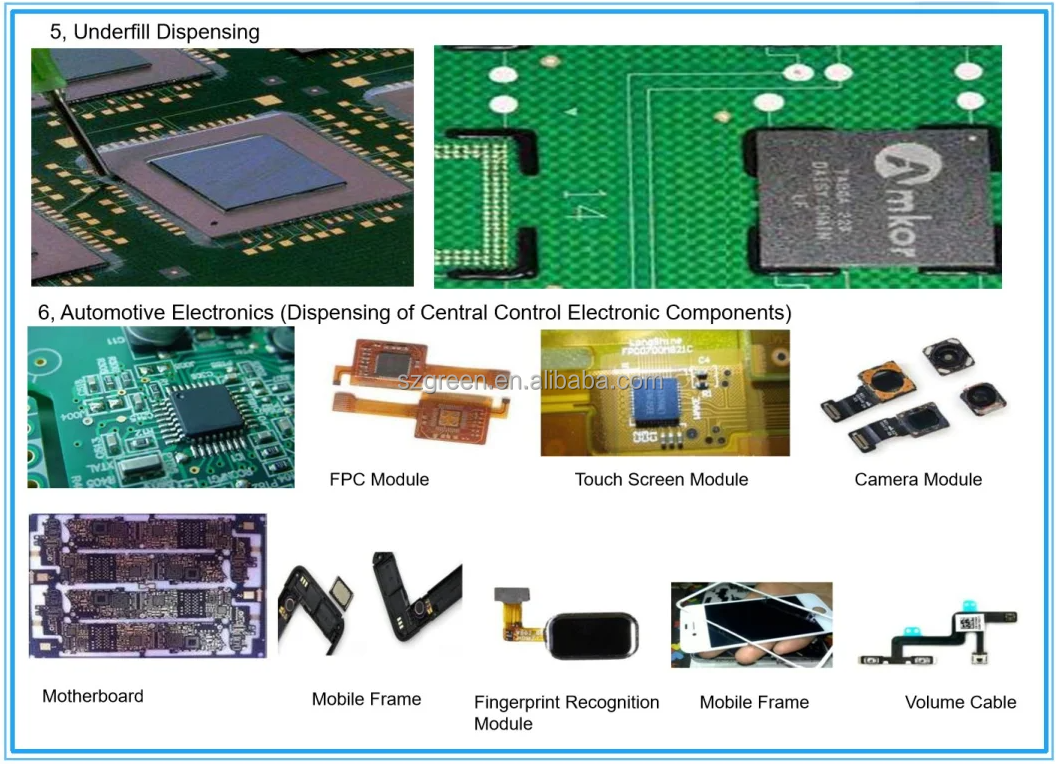

Detailed diagram

Laser Replacement Sensor

automatically identify the displacement deviation caused by product deformation, and compensate for the height to avoid the occurrence of glue stacking and glue breakage.

CCD Positioning

three-color coaxial light source imaging, positioning the MARK point of the scanning path,

to ensure the consistency of the dispensing position.

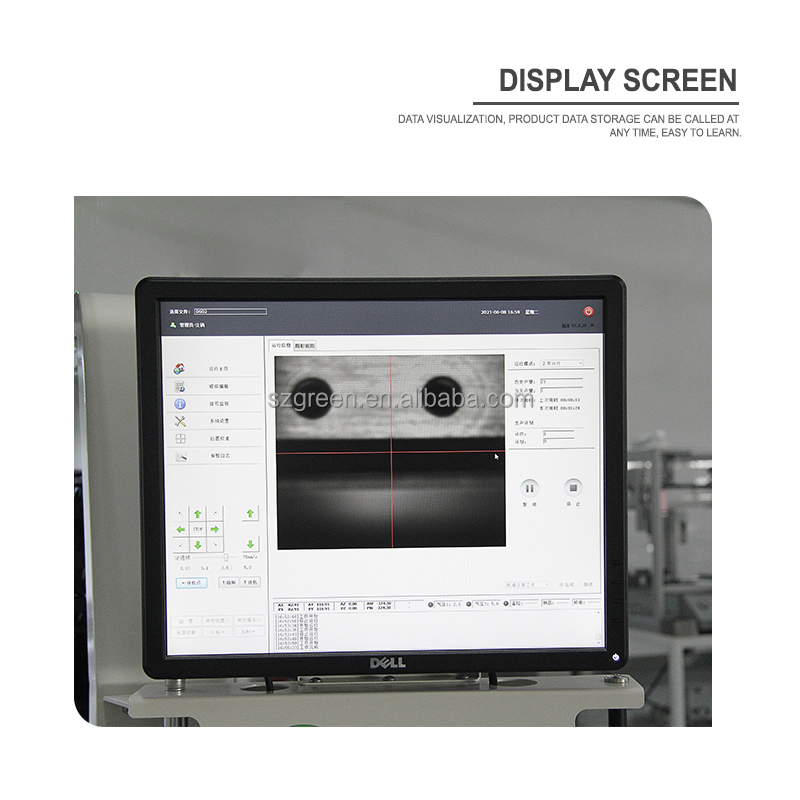

High-definition display screen

data visualization, product data storage can be called at any time, easy to lear