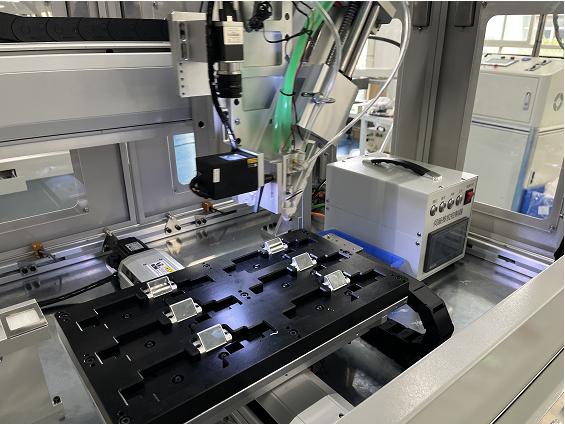

Green floor vision dispensing machine GR-FD10

Device Parameter:

| Model | GR-FD10 |

| X-axis | 550mm |

| Y-axis | 300mm |

| Z-axis | 100mm |

| Z-axis load | 10Kg |

| Y-axis load | 8Kg |

| XY moving velocity | 0~800mm/sec |

| Z moving velocity | 0~300mm/sec |

| Minimum diameter of spray glue | 0.2mm(depending on glue properties) |

| Repeatability | ± 0.02 mm/ Axis |

| keywords | gluing machines |

| Drive mode | Stepper motor + synchronous belt + precision guide rail |

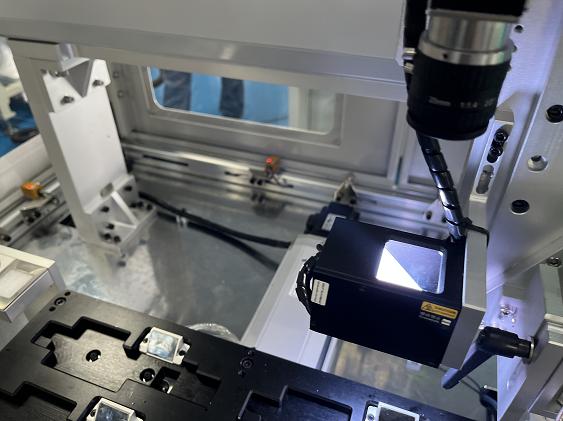

| Camera | 1.3 megapixel /5 megapixel option |

| Outer demension(L*W*H) | L(1200)*W(950)*H(1910) |

| Input power supply | 220V/50HZ |

| Driving mode | Servo motor + precision screw + precision guide rail |

| Display mode | Monitor |

Device features:

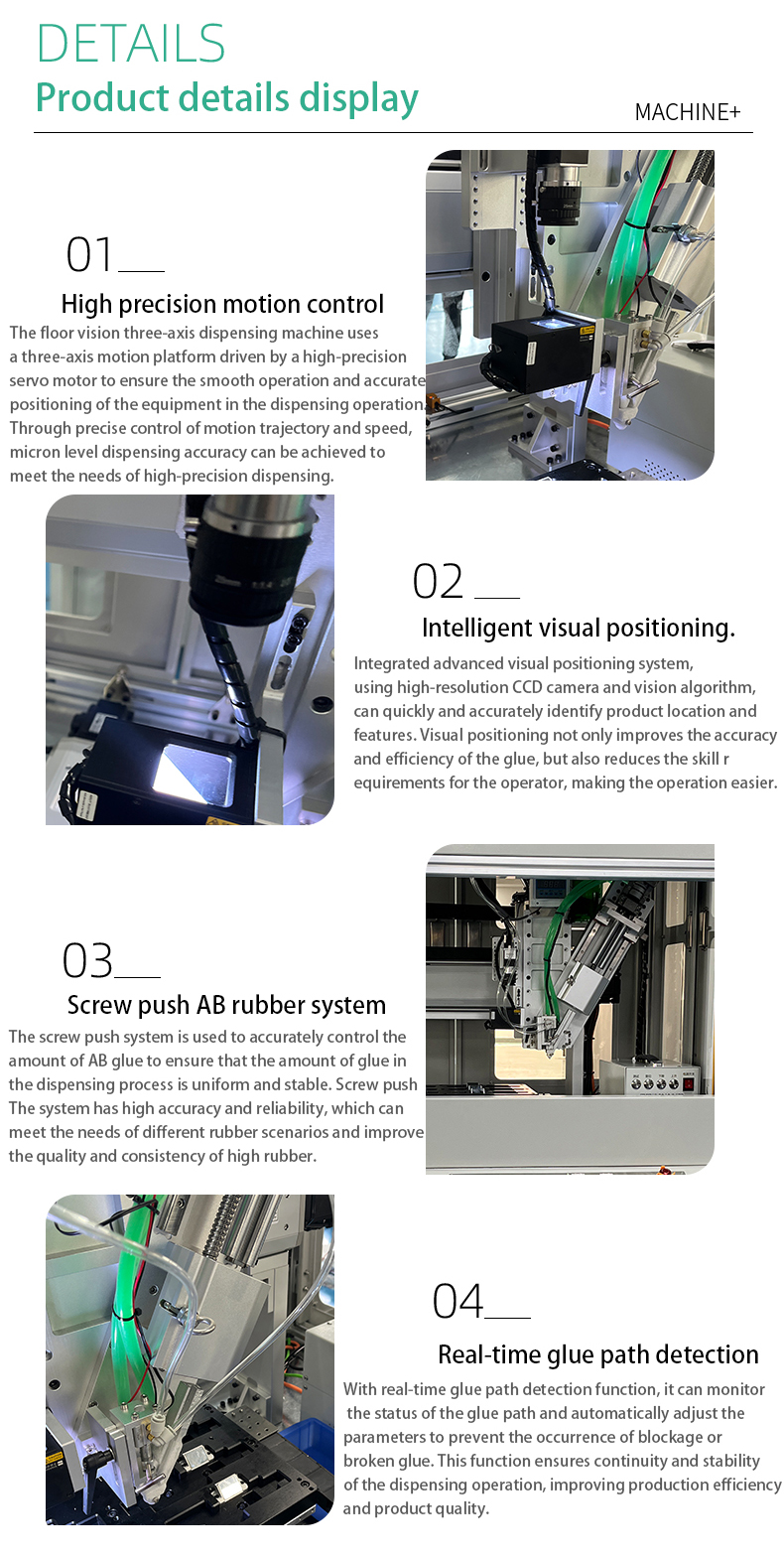

1.High precision motion control The floor vision three-axis dispensing machine uses a three-axis motion platform driven by a high-precision servo motor to ensure the smooth operation and accurate positioning of the equipment in the dispensing operation. Through precise control of motion trajectory and speed, micron level dispensing accuracy can be achieved to meet the needs of high-precision dispensing.

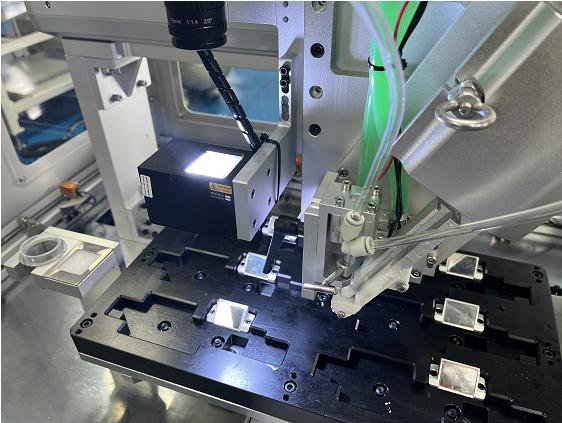

2.Intelligent visual positioning The device integrates an advanced visual positioning system that utilizes high-resolution CCD cameras and vision algorithms to quickly and accurately identify product locations and features. Visual positioning not only improves the accuracy and efficiency of the glue, but also reduces the skill requirements for the operator, making the operation easier.

3.Screw push AB rubber system The equipment adopts screw push system to accurately control the amount of AB glue to ensure that the amount of glue in the dispensing process is uniform and stable. The screw push system has high accuracy and reliability, which can meet the needs of different glue scenes and improve the quality and consistency of high glue.

4. CCD two-dimensional code scanning function By integrating CCD two-dimensional code scanning function, the device can quickly identify the two-dimensional code information on the product to achieve product traceability and batch management. This capability increases the transparency and control of the production process, contributing to improved product quality and customer satisfaction.

5.Real-time rubber path detection The equipment has real-time glue path detection function, which can monitor the status of the glue path and automatically adjust the parameters to prevent the occurrence of blockage or glue breaking. This function ensures continuity and stability of the dispensing operation, improving production efficiency and product quality.

6. Humanized operation interface The device is equipped with an intuitive and friendly operation interface, which is convenient for the operator to set parameters and monitor the dispensing process. The interface design is simple and clear, the operation is convenient, and the operation difficulty and the risk of misoperation are reduced.

7.Stable and reliable performance The floor-mounted visual three-axis dispensing machine is made of high quality materials and precision machining technology, with good stability and reliability. The equipment can work continuously for a long time and maintain stable dispensing performance to meet the needs of large-scale production.