Green Floor Type Industrial Robot Automatic Liquid Glue Dispenser Machine

Specifications

|

Brand Name |

GREEN |

|

Model |

GR-FD03 |

|

Product Name |

Dispensing Machine |

|

Lock Range |

X=500, Y=500, Z=100mm |

|

Power |

3KW |

|

Repeatability Accuracy |

±0.02mm |

|

Dive Mode |

AC220V 50HZ |

|

Outer Demension(L*W*H) |

980*1050*1720mm |

|

Key Selling Points |

Automatic |

|

Place of Origin |

China |

|

Warranty of core components |

1 Year |

|

Warranty |

1 Year |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Showroom Location |

None |

|

Marketing Type |

Ordinary Product |

|

Condition |

New |

|

Core Components |

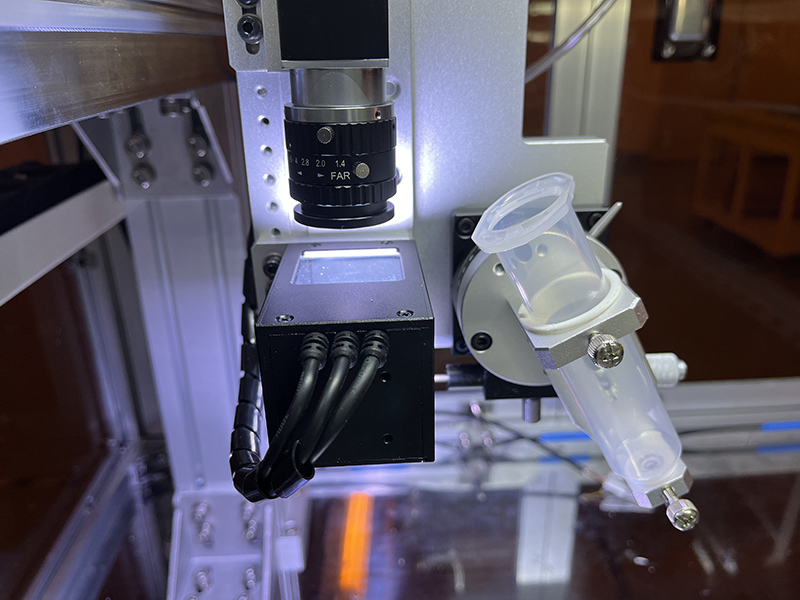

CCD, Servo motor, Grinding screw, Precision guide rail |

|

Applicable Industries |

Manufacturing Plant, Other, Communications Industry, LED Industry, Electronics Industry, 5G, Electronic Industry |

Feature

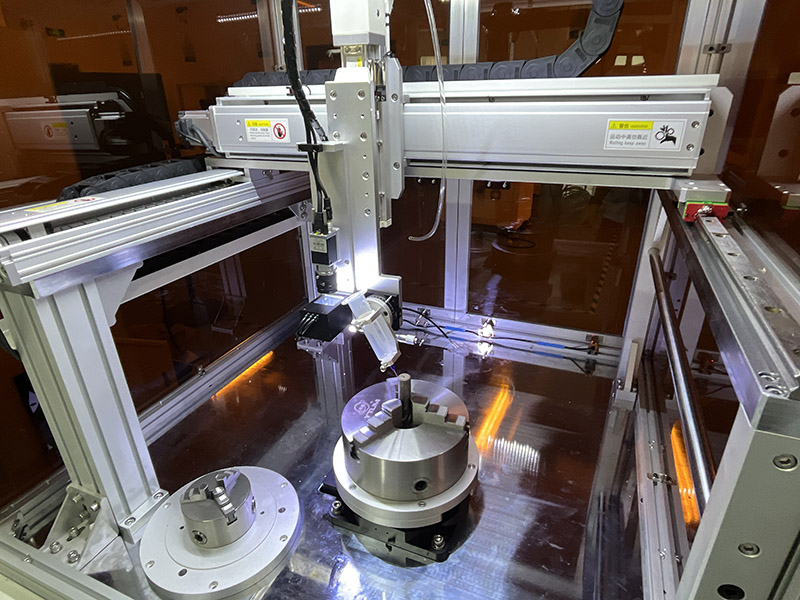

GREEN GR-FD03 Floor Type Dispensing Machine

- The equipment is aimed at circular products, manual loading and unloading, automatic visual recognition, accurate calculation and automatic correction of the dispensing path

- According to different dispensing requirements, dispensing speed/dispensing amount/dispensing trajectory (spatial point, line, arc, etc.) can be set separately

- Precision back suction controller, imported solenoid valve, with back suction function, accurate dispensing trajectory, uniform glue discharge, crisp glue breakage, no wire drawing, no glue dripping.

- A variety of dispensing needles, syringes, dispensing valves and controllers are available to meet different requirements, and the air pressure can be adjusted to control the amount of glue.

- Visual recognition Mark, accurate calculation, automatic correction of dispensing path

- Drive mode: servo motor + precision screw + precision guide rail drive, servo motor with hollow rotary table, effectively improve the motion positioning accuracy and repeatability

- Special visual dispensing operation software simplifies dispensing

- Program files can be uploaded/downloaded through U disk, which is convenient for data management and storage.

Diverse Applications

Multi-function High Speed Dispenser

Equipped with fine volume control and positional accuracy which allows it to dispense discrete dots. D Series Machine can dispense into tight locations or close to a component in very thin lines without going out of bounds. Through non-contact dispensing, problems that are brought about by conventional dispensers are completely eliminated

High Profile Ic, Qfp Bonding With Dots Stacking

Stackable dotting process can create high profile dotting to ensure components will be glued strongly to the PCB. No tailing effect unlike other conventional smt dispenser.

Pth Anti-Bridging Line Dispensing

By jetting lines of glue between a series of PTH leads with narrow lead pitch such as connectors and sockets, solder bridging can be eliminated during wave soldering process.

Corner Bonding

Corner bonding application can be done using our D-Sniper smt dispenser in a single SMT reflow process without any additional investment. SMA is dispensed on the PCB at the corners of BGA prior to placing the BGA. This application is not achievable by traditional contact dispensing as it is unable to create shapes and patterns thats adapted in Corner bonding. Through this application, there will be additional shock and bending resistance provided to the assembly when the PCB undergoes reflow.

Conformal Coating

Developed to protect components from dust, vibration, moisture, & other environmental condition, offering the longest possible operational lifespan for electronic devices. Without additional investment of conventional spray coating machine, D-Sniper can be converted into a jet coating machine

Underfill

With an adequate amount dispensed (the smallest mark being 0.3mm), it ensures components remain robust & safely secured. The Precision Material Weight Calibration System (Option) would ensure a consistent underfill material volume being applied to every component.

Smt Chip Bonding

GR-FD03 Machine capable to dispense (dot) red glue for mix technology PCB bottom side assembly to enhance mechanical bond strength.

Technology Center

Benefit from our expertise and many years of experience. Develop the optimum process for your requirements together with us. We are specialists for different applications and processes.

Experience & know-how

Our process experts are in close contact with material manufacturers and have many years of experience in process development and processing, even with challenging materials.

Procedure of a trial in our Technology Center

In order to optimally prepare a process trial, we need the material to be processed, for example an impregnating resin, a thermally conductive material, an adhesive system or a reactive casting resin, in sufficient quantity with the corresponding processing instructions. Depending on how far advanced the product development is, we work in our application trials with prototypes up to original components.

For the trial day, specific targets are set, which our qualified personnel prepare and carry out in a structured, professional manner. Afterwards, our customers receive a comprehensive test report in which all tested parameters are listed. The results are also documented in pictures and audio. Our Technology Center staff will support you in defining the process parameters and make recommendations.