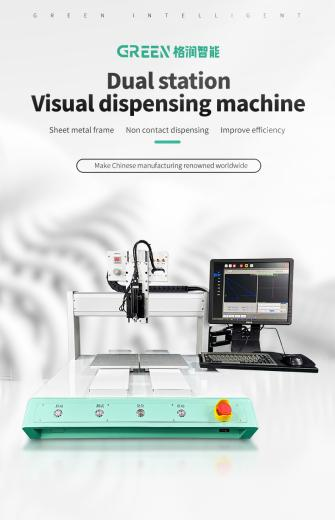

Green Desktop visual dispensing machine GR-DT4221-M gluing machines

Device Parameter

| item | value |

| Basic parameters | GR-DT4221-M (servo motor type) |

| Electricity demand | AC220V 50/60Hz 1.5KW |

| Brand Name | Green |

| Pressure demand | >0.6Mpa |

| External dimensions(mm) | 810*710*700mm(D*W*H) |

| Sports distance(mm) | 400*200*200*100 |

| Weight (kg) | one hundred and five |

| Certification standards | CE |

| Positioning accuracy(mm) | 士 0.02 |

| Repetitive accuracy(mm) | XY: ± 0.012 |

| Maximum speed (mm/s) | 600(XY),300(z) |

| Maximum acceleration | 0.4g |

| Z-axis load (kg) | six point five |

| Worktable load (kg) | twenty |

| image sensor | High definition industrial camera |

| Driving method | Ball screw |

| driving system | Servo motor |

| Programming method | Visual programming |

| software platform | Dispec software platform |

Device features

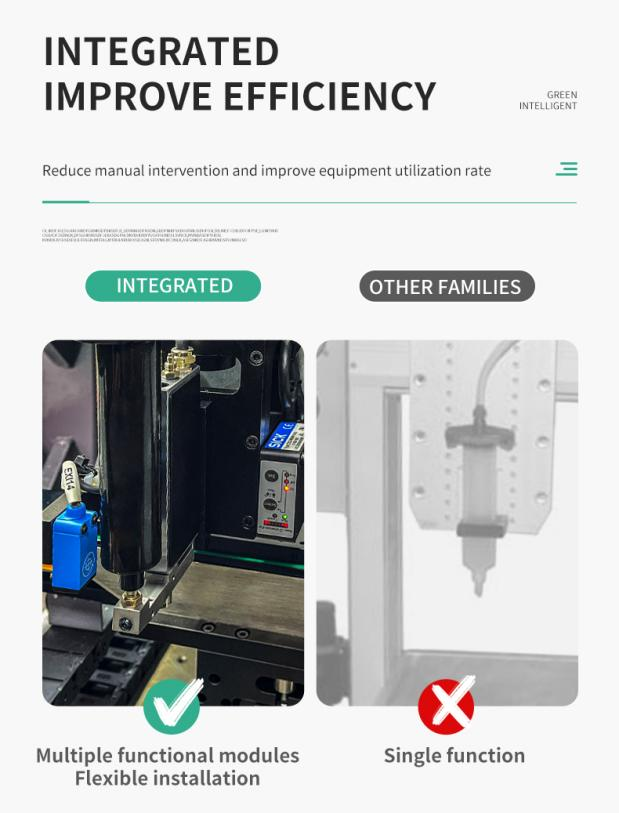

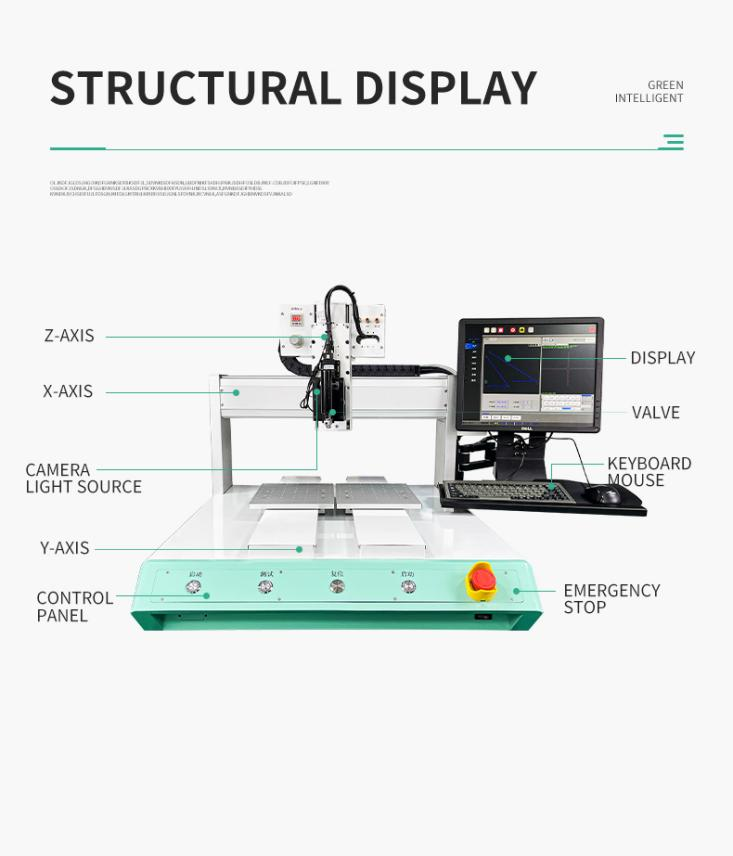

The equipment adopts a stable mechanical structure and screw drive design to ensure the running accuracy of the X/Y/Z triaxes of the machine during high-speed movement and achieve the ideal dispensing effect.Match different kinds and the number of valve body configurations can improve production efficiency and meet the dispensing requirements of different.

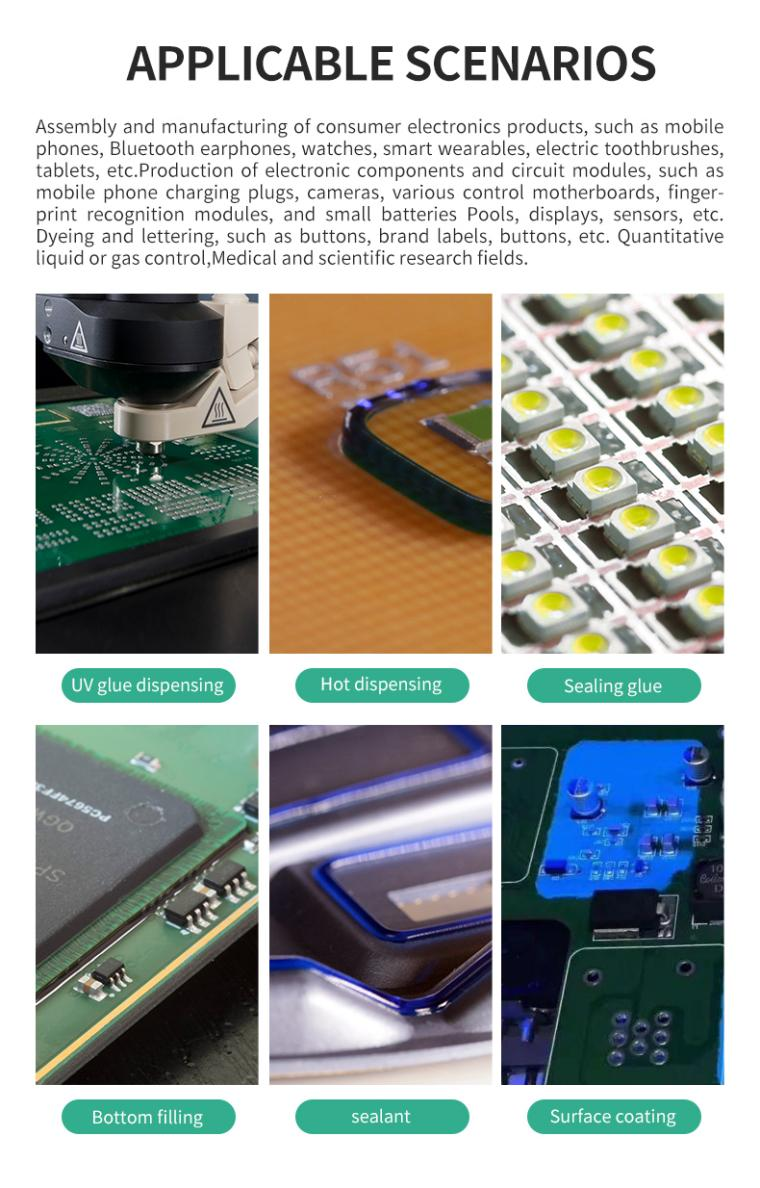

1.Suitable for most glues on the market,such as underfill glue,silica gel,silver paste,hot melt glue,thread glue,red glue,UV glue, three-proof glue,etc.

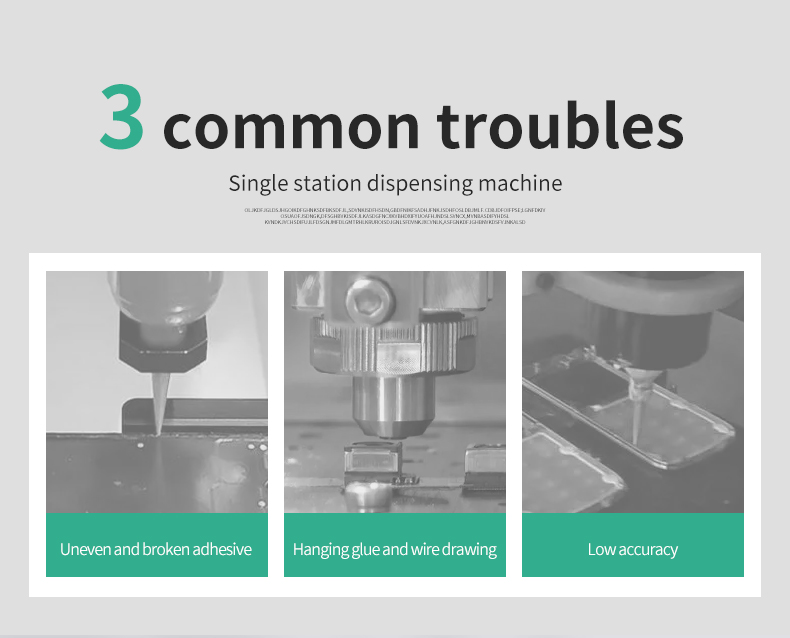

2.Continuous path dispensing to achieve the continuity of dispensing speed and direction throughout the jet dispensing process; It is especially suitable for high-speed continuous motion dispensing where small devices are closely connected.

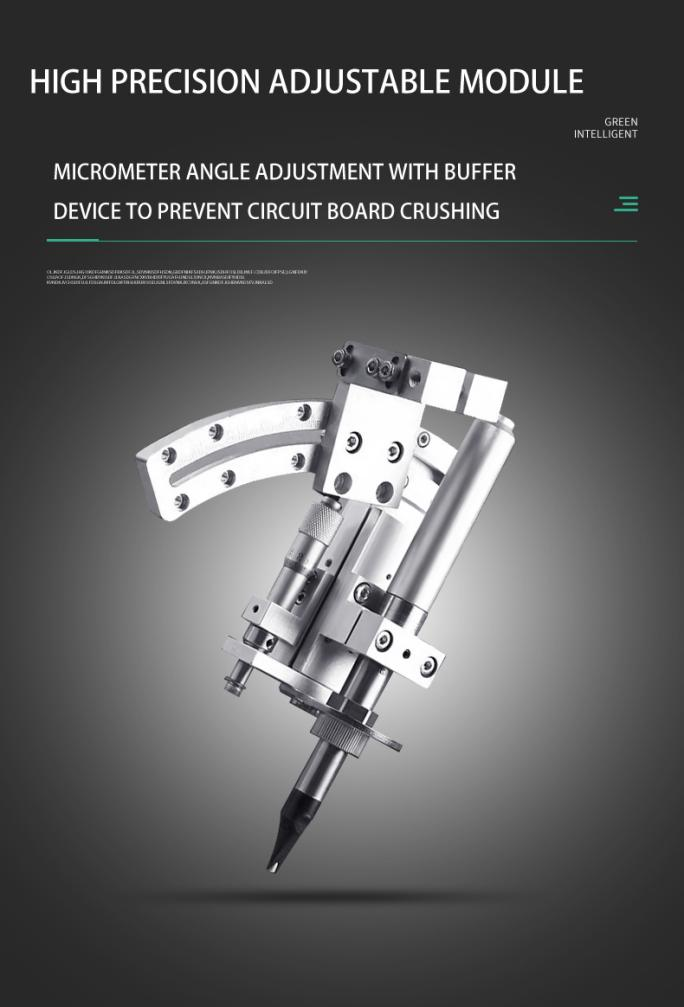

3.Adopt stable mechanical structure and screw drive design to ensure the running accuracy of XYZ three axes in the process of high-speed movement.The user-friendly software interface guarantees simplicity and ease of use.

4.Low liquid level alarm of fluid to reduce defects caused by insufficient glue. 5.Innovative one-key correction reduces manual operation as much as possible,improves efficiency,and improves the dispensing difference of different machines.

6.Automatically generate inspection reports to provide strong data support for subsequent yield analysis and product traceability analysis.

Details Show