Green Automatic Intelligent Online Screw Locking Machine

Specifications

|

Brand Name |

GREEN |

|

Model |

GR-OL-200L |

|

Product Name |

Screw Locking Machine |

|

Lock Range |

X=200, Y=200, Z=70mm |

|

Power |

1.5KW |

|

Repeatability Accuracy |

±0.02mm |

|

Dive Mode |

AC220V 50HZ |

|

Weight (KG) |

400 KG |

|

Outer Demension(L*W*H) |

1000*645*1520mm |

|

Key Selling Points |

Automatic |

|

Place of Origin |

China |

|

Warranty of core components |

1 Year |

|

Warranty |

1 Year |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Showroom Location |

None |

|

Marketing Type |

Ordinary Product |

|

Condition |

New |

|

Core Components |

Motor, Screw, Guide rail, Batch, Blowing type feeder, Handheld programmer |

|

Applicable Industries |

Manufacturing Plant, Mobile phone industry, Toy industry, Appliance industry, Electronic industry |

Feature

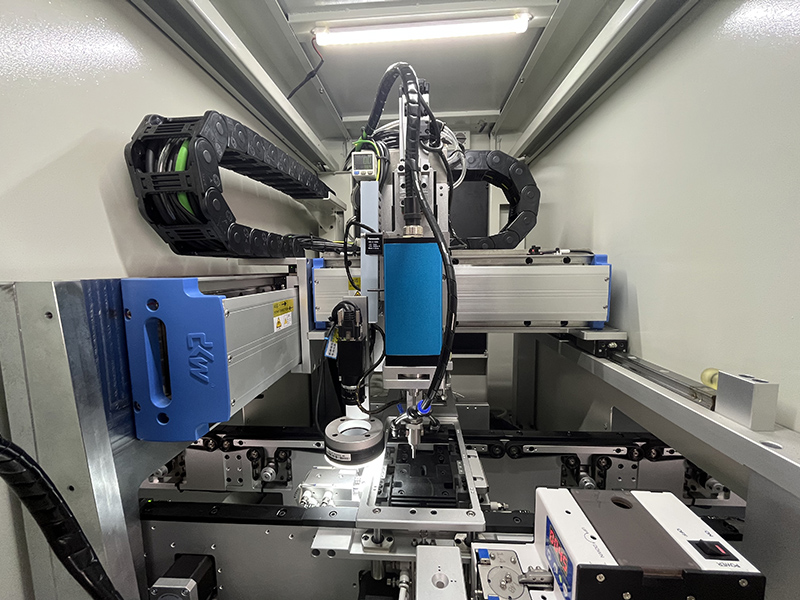

Online Robot Screw Machine of GREEN GR-OL-200L

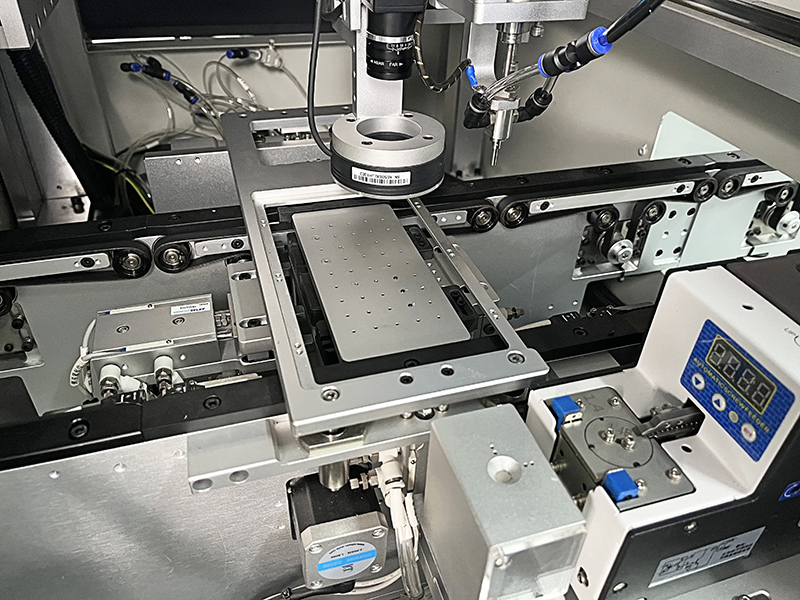

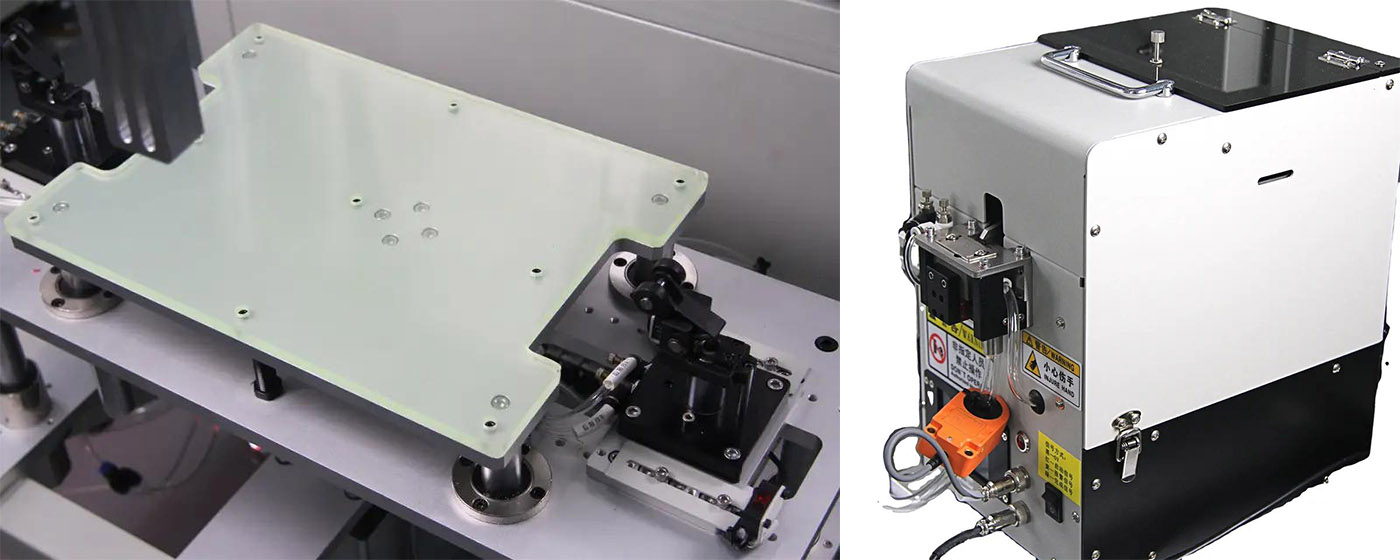

- Stand-alone online structure, adjustable track width, long side of mobile phone parallel to track flow, covering 5~7 inch mainstream mobile phone product size range

- PC motion control system, visual programming, unlimited data saving

- Support CAD point coordinate import

- CCD assists the teach-in screw coordinate point to eliminate the manual visual positioning error

- CCD visual positioning corrects coordinate points, and multiple groups of Mark points are intelligently combined to improve the photo pass-through rate

- Graphical display of lock points and lock results, automatic marking of OK/NG screw points, intuitive and fast search

- Configure intelligent electric batch, and set the torque and speed at any point separately

- Configure screw float height displacement sensor to automatically detect and repair screws with poor float height

- Equipped with pressure detection sensor, automatically detect and monitor the downforce of the batch head on the product when locking

- Online torque spot check, storage torque spot check results and query

- Multi-user, multi-level authority management, administrators can create new accounts and assign software operation permissions

- With production statistics and traceability functions, each screw lock data is automatically saved and can be queried or exported *.xls files

- With MES connection function, automatically upload production data to MES system

Program description

. The equipment is used to lock the screw fastening on the product.

. Product features stable, efficient, high-precision, and flexible.

. Product flow positioning and clamping product CCD. positioning locking, screw positioning, clamping, manipulator reset product flow out to the next station.

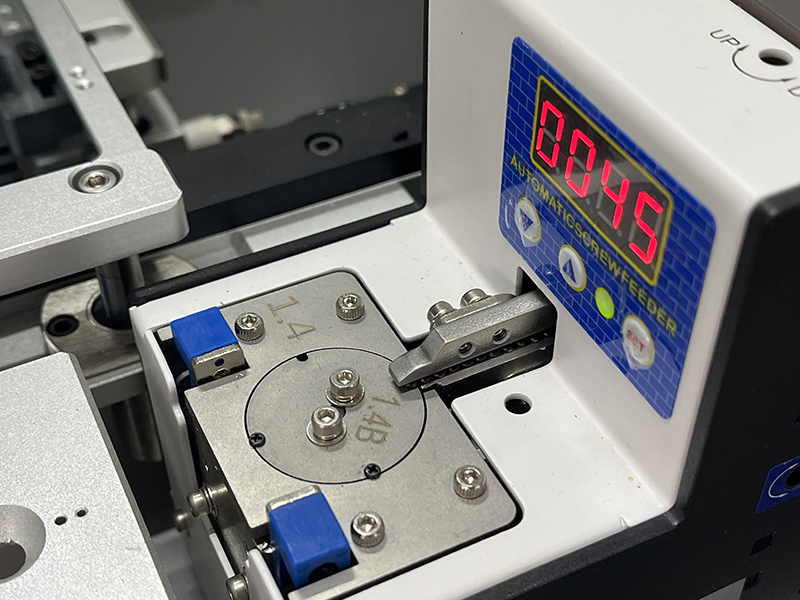

. Equipped with a double feeding system, which can realize two types of screw locking.

. Equipped with smart electric batch, support lead lock, slip tooth, floating height alarm.

. Robot + CCD + industrial computer, improve the accuracy of locking and intelligent programming.

Application range

The manipulator smart screw machine was born to solve the manual lock station of notebooks, all-in-ones, monitors, TVs, smart home appliances (sweeping robots, charging piles), smart wearable electronic products, new energy and other industries. Green screw machines replace the traditional XYZ platform screw machine. It’s suitable for mixed-line production, successfully solving industry difficulties. It has a rack-mounted and embedded working mode, and can be used for quick line change.

Technology Center

Benefit from our expertise and many years of experience. Develop the optimum process for your requirements together with us. We are specialists for different applications and processes.

Experience & know-how

Our process experts are in close contact with material manufacturers and have many years of experience in process development and processing, even with challenging materials.

Procedure of a trial in our Technology Center

In order to optimally prepare a process trial, we need the material to be processed, for example an impregnating resin, a thermally conductive material, an adhesive system or a reactive casting resin, in sufficient quantity with the corresponding processing instructions. Depending on how far advanced the product development is, we work in our application trials with prototypes up to original components.

For the trial day, specific targets are set, which our qualified personnel prepare and carry out in a structured, professional manner. Afterwards, our customers receive a comprehensive test report in which all tested parameters are listed. The results are also documented in pictures and audio. Our Technology Center staff will support you in defining the process parameters and make recommendations.