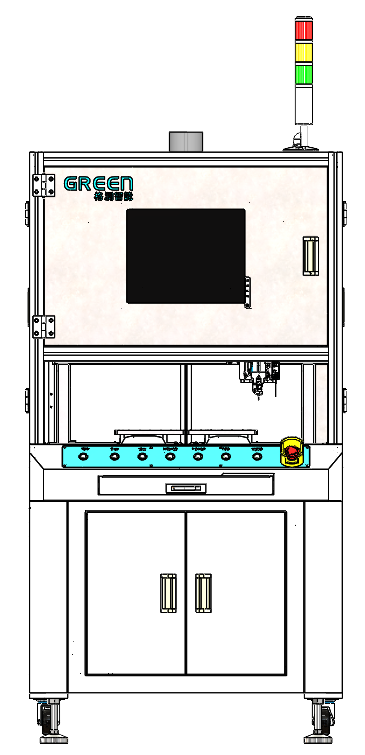

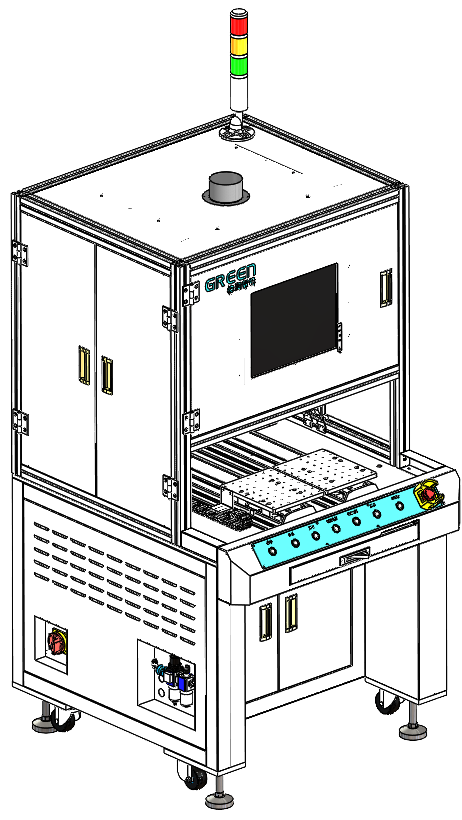

Green automatic Double-station all-in-one glue dispensing machine GR-FS4221-M

Device Parameter

| Model | GR-FS4221-M |

| Power demand | AC220V 11A 50/60Hz 2.5KW |

| Air pressure requirement | 90psi(6bar) |

| Dimensions | 900*1000*1700mm(W*D*H) |

| Weight | 400KG |

| Accreditation standards | CE |

| Dispensing range | X1 X2:200mm Y1 Y2:200mm Z: 100mm |

| Number of spindles | X, Y1, Y2, Z |

| XYZ axis positioning accuracy | ±0.025mm |

| XYZ axis repetition accuracy | ±0.012mm |

| keywords | dispenser machine |

| Max speed | 800mm/s(XY) 500mm/s (Z) |

| Acceleration | 0.8G |

| Drive system | servo motor + screw module |

| Track bearing capacity | 5KG |

| Control mode | Industrial computer + motion control card |

| Orbital ground clearance | 900±20mm |

| Standard Configuration |

| CCD visual positioning |

| XYZ axis datum correction system |

| Optional Configuration |

| AOl visual glue inspection |

| 3D scanning/path guidance |

| Laser altimetry (Keyence/SICK) |

| The needle is automatically aligned |

| Lack of glue alarm |

| Needle/nozzle cloth wrap cleaning module |

| Nozzle vacuum cleaning module |

| Industrial barcode/QR code identification system |

| Safety light curtain at the front entrance |

| Non-contact product preheating module |

| Air Tank Booster Pump/Electric Proportional Valve (for high-precision glue dispensing) |

Device features

1.Each axis adopts advanced servo motor and confidential ball screw to ensure the high speed,high precision and high consistency of the machine movement

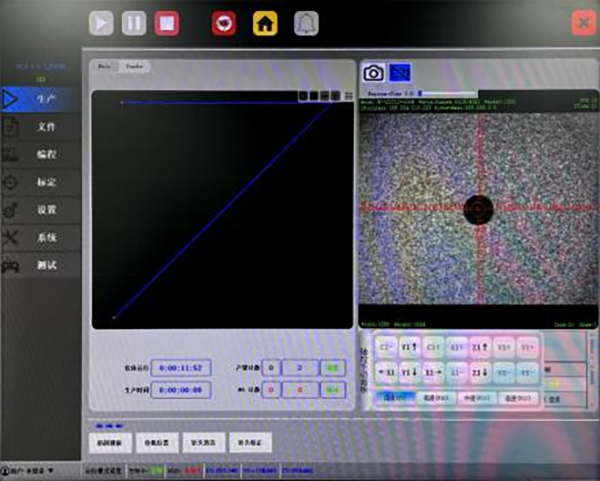

2.The main control system is directly programmed by control card,touch screen or industrial computer

3.The programming interface is simple and clear,and common graphics(circles,ellipses,rectangles,etc.)can be directly input and invoked

4.Support CAD image import and trajectory preview function

5.Semi-enclosed shell design,easy to operate,improve the cleanliness of the dispensing environment

6.The equipment adopts the design mode of overall processing and modular installation mode to ensure high precision and easy maintenance

7.Strong bearing capacity and large internal space of the equipment

Green Double-station all-in-one dispensing machine GR-FS4221-M

*Optional visual positioning system, laser height measurement, liquid level detection, automatic needle, needle cleaning and other auxiliary function modules to achieve function customization, to meet most of the dispensing operations.

The machine can be equipped with non-contact piezoelectric injection valve to improve dispensing accuracy, safety, convenience, reliability and other high-precision dispensing operations.

*A each axis adopts advanced servo motor and confidential ball screw to ensure high speed, high precision and high consistency of machine movement.The main control system adopts control card, touch screen or industrial computer directly programming.The programming interface is simple and clear, and the commonly used graphics (circle, ellipse,rectangle, etc.) can be called directly by input parameters.

*Support CAD image import and track preview function. Semi-closed shell design, easy to operate at the same time, improve the cleaning of the glue environment. The equipment adopts the design method of whole processing and the modular installation method to ensure high precision and easy maintenance. The bearing capacity is strong and the internal space of the equipment is large.

Advantageous applications

1.undefill 2. pin encapsulating 3. conformal coating 4. package on package 5.Underfil 6.SMT red glue process 7 .COB package