Fully automatic dispensing machine for various dispensing applications

Specifications

| Brand Name | GREEN |

| Model | DP500D |

| Product Name | Dispensing Machine |

| Platform Itinerary | X=500, Y1=300, Y2=300, Z=100mm |

| Repeatability | ±0.02mm |

| Dive Mode | AC220V 10A 50-60HZ |

| Outer Demension(L*W*H) | 603*717*643mm |

| Weight(KG) | 200KG |

| Key Selling Points | Automatic |

| Place of Origin | China |

| Warranty of core components | 1 Year |

| Warranty | 1 Year |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Condition | New |

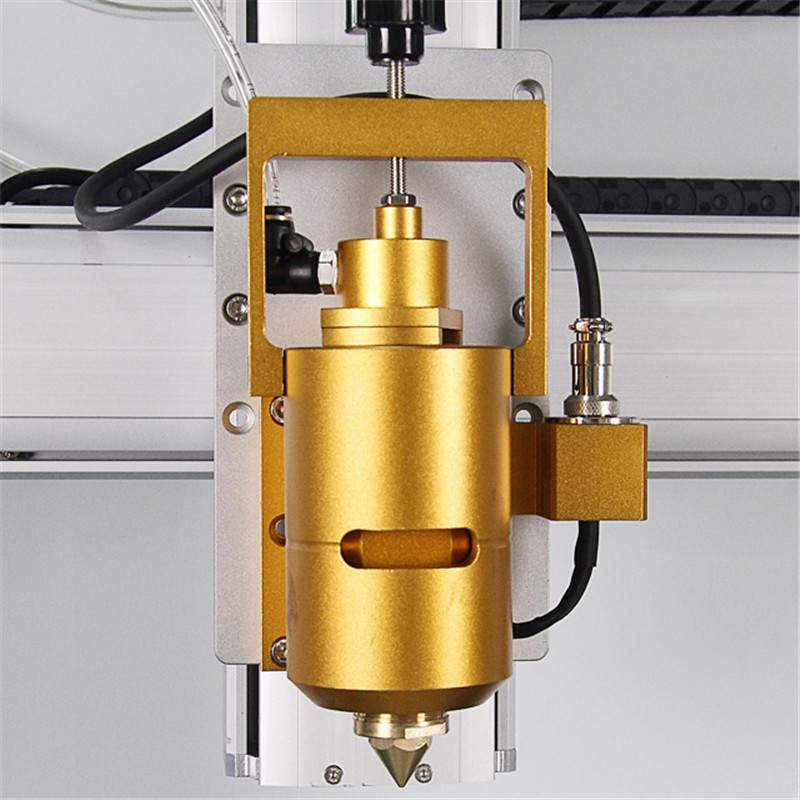

| Core Components | Servo motor, Grinding screw, Precision guide rail, Stepping motor, Synchronous belt, Valve |

| Applicable Industries | Manufacturing Plant, Other, Communications Industry, LED Industry, Electronics Industry, Toy Industry, 5G |

Feature

● High-speed operation without jitter,convenient disassembly,simple maintenance,and cost-effective.

● Fully automatic cell with 4 axis system,

● Dispensing of single and multi-component materials,

● Menu-driven visualization with operator guidance and operating levels,

● Stability control system, Lean machine design

● Freely adjustable mixing ratio, Simple and fast commissioning

● Flexibility for integration into production lines

● High degree of automation,Operating data logs

Fully automatic dispensing systems solve all kinds of dispensing tasks precisely and reliably. Due to the high degree of automation, our market-driven solution increases productivity while maintaining the highest quality.

Dispensing Methods

Bonding: Adhesive bonding is a dispensing process used to join two or more parts together. Adhesive bonding processes are becoming increasingly established as a field of application in dispensing technology.

Through the dispensing method bonding, two or more joining partners are joined together. Effective bonding enables a material-to-material bond without introducing heat and causing possible damage to components. Ideally, in the case of plastic parts, activation of the surface takes place by means of atmospheric or low-pressure plasma. During application, the surface and material remain unchanged. Bonding therefore does not affect factors of the component such as mechanics, aerodynamics or aesthetics.

As a rule, the process consists of two steps: First, the adhesive is applied and then the parts are joined. In this process, the adhesive is applied to defined areas on the outside or inside of the component. Crosslinking of the adhesive takes place through material-specific properties. In addition to a variety of industrial sectors such as medical technology, electronics production, lightweight construction, this dispensing process is frequently used in the automotive sector. Adhesive bonding is used, for example, in electronic control units, LiDAR sensors, cameras and many more.

Get in touch with us as early as possible in the product development phase. Our engineers and technicians can provide advice on component optimization and practical experience can be taken into account. This helps you and us to transfer your products into series production.

Based on the selected material, component and production requirements, we define the process parameters for series production together with our customers. More than 10 specialists from various professional disciplines, ranging from chemists with doctorates and engineers to plant mechatronics engineers, are on hand to provide our customers with advice and support.