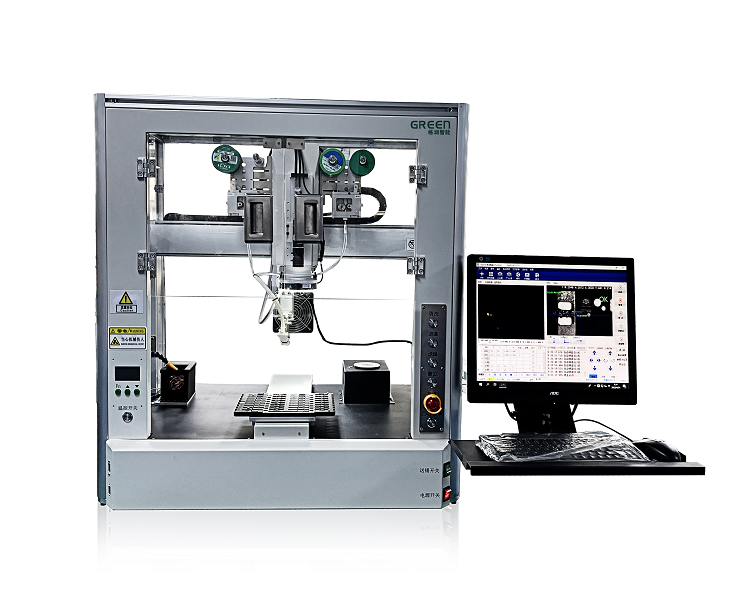

Dual-vision soldering machines SI641R wire soldering 220V soldering irons soldering machines

Device Parameter

|

Item |

Specifications |

|

Model |

SI641R |

|

X-axis |

600mm |

|

Y-axis |

400mm |

|

Z-axis |

100mm |

|

Z-axis load |

3Kg |

|

Y-axis load |

10Kg |

|

the maximum movement sped of theY axis |

0~500mm,sec |

|

The maximum moent speed of the Z-axis |

0~250mm,sec |

|

±0.02 mm,Axis |

±0.02 mm,Axis |

|

Mode of operation |

inch monitor+motion control card |

|

keywords |

Hot Air Soldering Machine |

|

Drive mode |

Stepper motor + synchronous belt + precision guide rail |

|

Enter the power supply |

220V,50HZ |

|

Outer demension(L*W*H) |

820*643*915(mm) |

Device features

1.Flexible and diverse soldering methods,with spot welding,drag welding (pull welding)and other functions:

2.Modular structure design,easy to maintain and maintain;

3.Customized multi-tin feeding module,which can quickly add tin feeding module according to application needs,which can meet the one-time soldering process of multiple pads of different sizes on the board;

4.The central smoke extraction system minimizes the pollution of the flux to the air and the soldering module;

5.Flexible programming system to meet diverse customer needs;

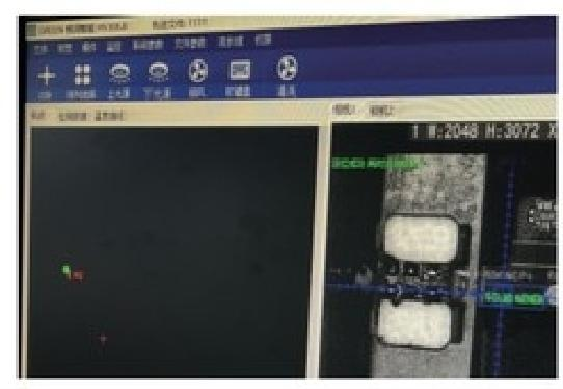

6.Equipped with dual vision system,the upper vision is used for positioning the system function,and the lower vision is used to correct the angle of the soldering iron tip (for multi-tin feeding module);

7.The equipment has an automatic cleaning function,which stabilizes the quality of solder proc essing and prolongs the service life of the soldering tip to a certain extent;

8.Built-in temperature real-time monitoring system;

9.The welding module of the equipment is equipped with automatic buffering function to avoid damage to the welding products during equipment debugging and operation;

10.The thermostat can adjust the temperature range between 5-450 degrees Celsius, accurate to ±5 degrees Celsius, constant temperature control, fast warming;

11.Drive mode: stepper motor + synchronous belt + precision rail drive;

Application Range

Mobile phone, computer, integrated circuit, tablet, digital automotive industry, battery assembly, loudspeaker, PCB board, semiconductor microelectronics assembly, camera module soldering.