Floor-Type Blue Light Laser Soldering Machine With High Precision CCD System LAW501

Specifications

|

Brand Name |

GREEN |

|

Model |

LAW501 |

|

Product Name |

Laser Soldering Machine |

|

Platform Itinerary |

X=400, Y=400, Z=150mm |

|

Processing Range |

350*350mm |

|

Laser Wavelength |

445mm |

|

Maximum Laser Output Power |

40W |

|

Repeatability Accuracy |

±0.02mm |

|

Dive Mode |

AC220V 10A 50-60HZ |

|

Type |

Soldering Machine |

|

Laser type |

Blue light semiconductor laser |

|

Weld type |

Laser tin wire |

|

Weight (KG) |

200 KG |

|

Key Selling Points |

Automatic |

|

Place of Origin |

China |

|

Warranty of core components |

1 Year |

|

Warranty |

1 Year |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Showroom Location |

None |

|

Marketing Type |

Ordinary Product |

|

Condition |

New |

|

Core Components |

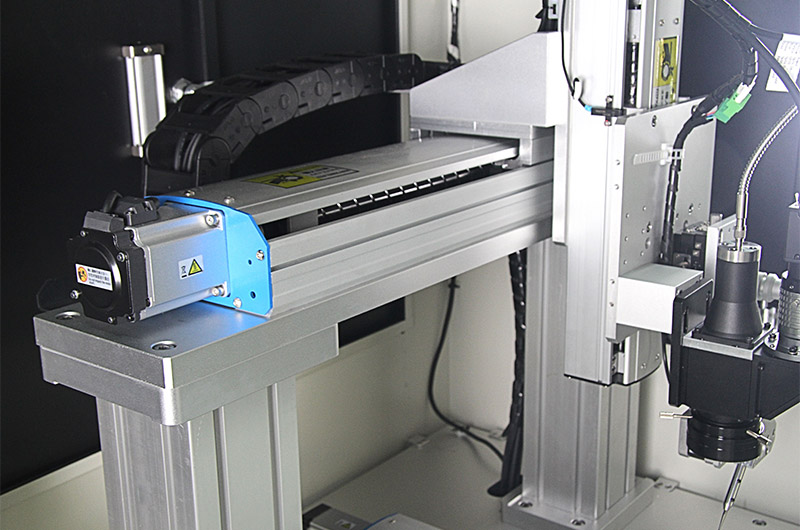

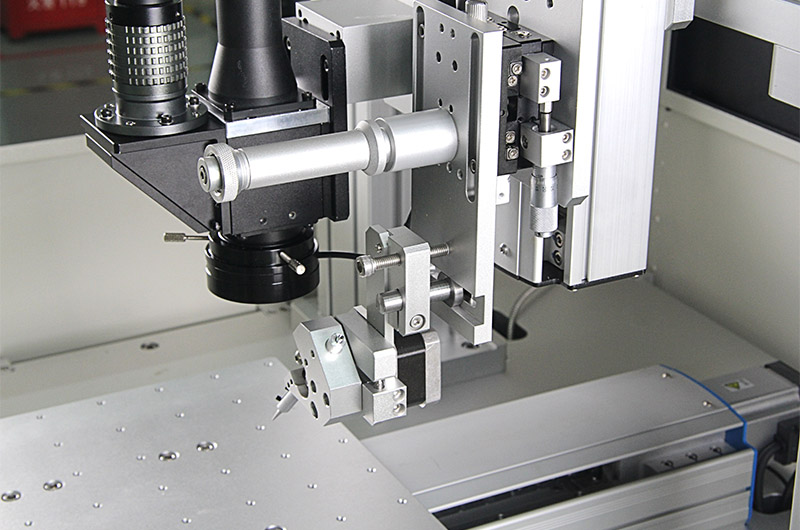

Motor, Industrial computer, Precision Guide Rail, Camera, Screw |

|

Applicable Industries |

Machinery Repair Shops, Manufacturing Plant, Other, Communication Industry, 3C Consumer Electronics Industry, Automobile Industry, New Energy Industry, LED Industry, Electronics Industry |

Feature

GREEN LAW501 Floor type Blue Light Laser Soldering Machine

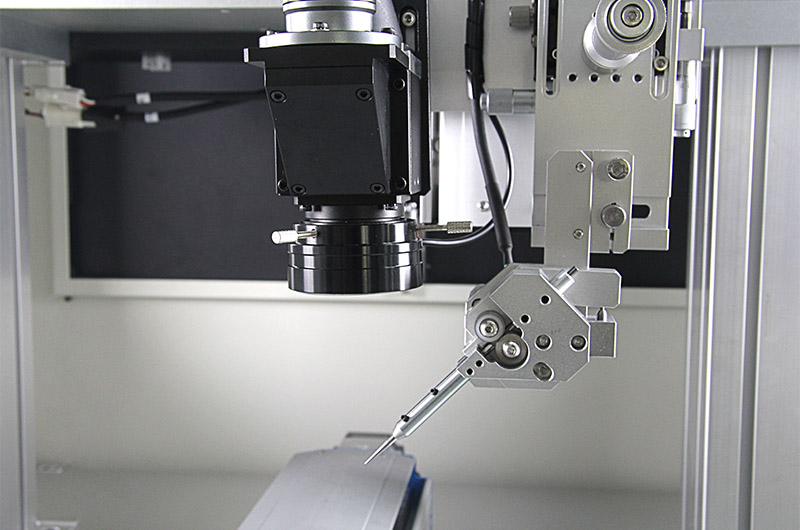

1. High precision: the light spot can reach the micron level, and the processing time can be controlled by the program, making the accuracy much higher than the traditional soldering process.

2. Non-contact processing: the soldering process can be completed without direct surface contact, so there is no stress caused by contact welding.

3. Small working space requirements: a small laser beam replaces the soldering iron tip, and precision processing is also performed when there are other interferences on the surface of the workpiece.

4. Small working area: local heating, the heat-affected zone is small.

5. The working process is safe: there is no electrostatic threat during the processing.

6. The working process is clean and economical: laser processing consumables, no waste is generated during the processing.

7.simple operation and maintenance: laser soldering operation is simple, laser head maintenance convenience.

8. Service life: The life of the laser can be used for at least 10,000 hours, with long life and stable performance.

Function

Automatic soldering of pins on different implementation of boards. The laser soldering can be used for the most different materials. The soldering robots disposes of a laser which solder connections carries out in the shortest time.

Automatic programming robot (automatic programmer)

Special Nomenclature: automatic programming robot, automatic burner, intelligent programmer, fully automatic programming device, fully automatic programmer, fully automatic burner, these special nomenclature actually is similar devices (instead of manual chip programming Of the fully automatic programmer, the following unified known as the chip fully automatic programmer)

Special Nomenclature: automatic programming robot, automatic burner, intelligent programmer, fully automatic programming device, fully automatic programmer,fully automatic burner, these special nomenclature actually is similar devices (instead of manual chip programming Of the fully automatic programmer, the following unified known as the chip fully automatic programmer)

Soldering Manager (for iron tip)

Visualization of the robot’s operational status, including coordinates for each point, various counters, tip temperature, etc.

All correction values by the 3-axis tip position correction mechanism, temperature measurement values by UNI-TESTER, automatic offset values, tip grounding resistance, and leakage voltage are recorded.

Video and data recording during soldering enhances traceability

Serial management by reading 2D codes

Global process control is possible by sharing acquired data