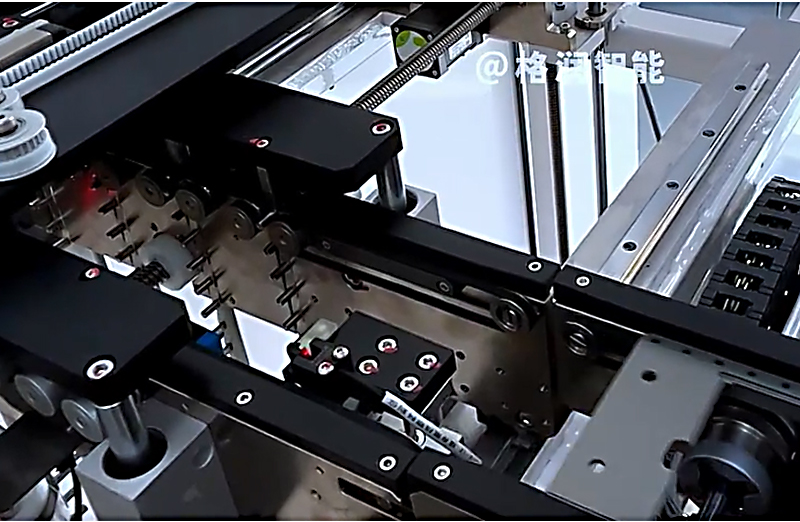

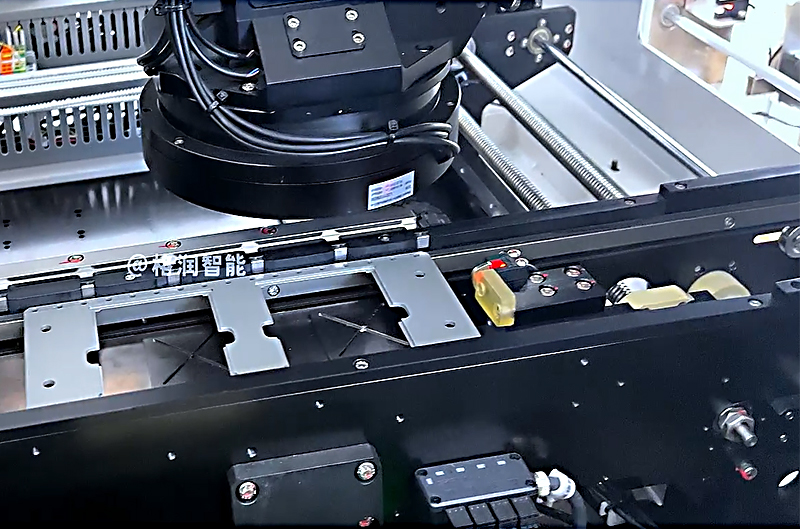

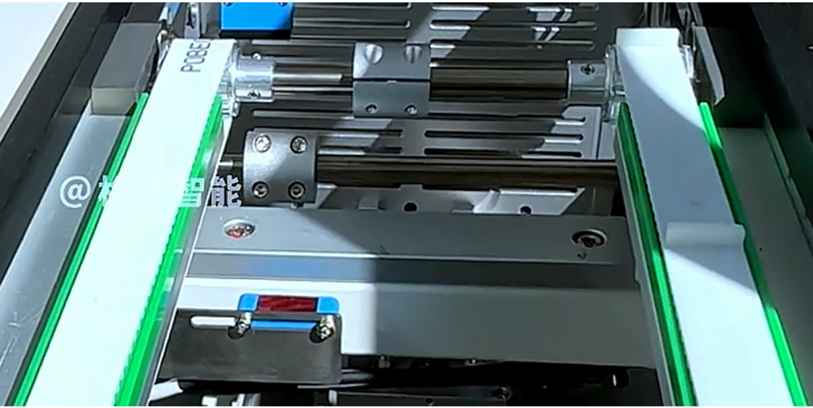

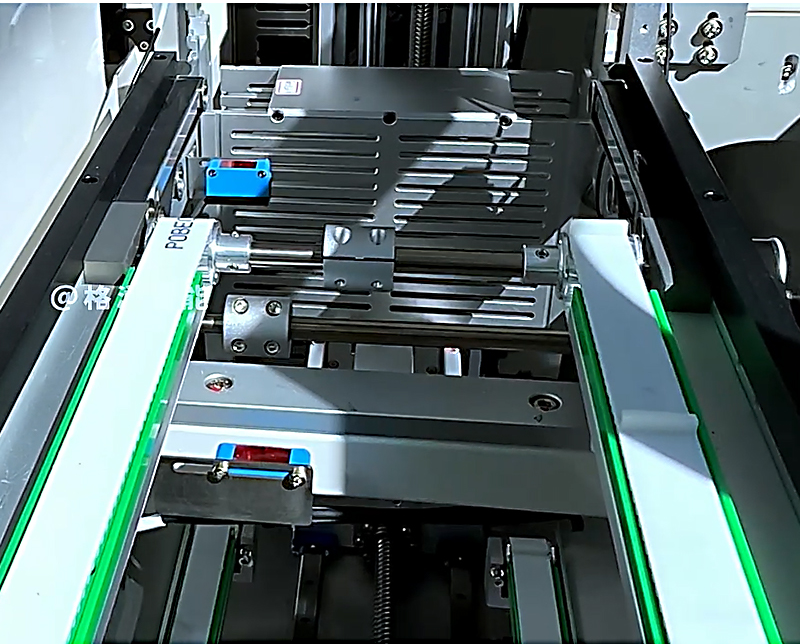

Automatic Offline Optical Inspection Detector AOI D-500 machine inspection

Device Parameter

| Place of Origin | China |

| Guangdong | |

| Brand Name | GREEN |

| Condition | New |

| Weight (KG) | 800 |

| Video outgoing-inspection | Provided |

| Marketing Type | Hot Product 2024 |

| Core Components | PLC, Motor |

| Applicable Industries | electronic industry, PCB industry, 5G industry, communication industry |

| Keywords | machine inspection |

| Model | AOI-D500 |

| Data management | UPH &GR&R |

| Source of information reading | the OR code of the vehicle and the blank |

| Information reading method | Scan gun |

| track width | 50~460mm |

| Sheet tracks | belt conveyor, motor drive mode |

| weight | 800KG |

| Defective identification method | Ink marking |

| loading mode | automatic |

| uploading mode | automatic |

Device features

Key features

1. Friendly man-machine interface, simple training can be quickly started

2. User can customize the defect code name

3. Customers can customize the defect code according to their needs

4. Traceable defect mapping data, support a variety of communication formats

5. Defective ink identification module

6. TCP/IP communication protocol

7. With SPC statistics and analysis function

8. Central control system option, remote operation management of multiple equipment

Vision algorithms

1. Professional solid-crystal & wire bonding visual inspection system

2. Nearly 100 kinds of solid crystal, bonding wire, frame, glue and Die surface defect special detection algorithms

3. Adaptive defect detection

4. Detection application algorithm for aluminum wire wedge welding design

Software

1. Using PC Based operating system, user-friendly operation interface, users can set the access rights of different groups according to their needs(the number of groups is unlimited)

2. It has detailed historical batch detection information, as well as missing circuit analysis and measurement analysis functions.

3. Can provide defective e mapping information to the post-process, the format is: csv file, txt text, html file HTTP APl requests Excel files SOLite data files.

4. When the device alarms, the interface clearly displays the information, and has the function of querying the historical alarm information record.

Details Show