AOI detection for chip resistance capacitance/LED/SOP TO/QFN/QFP/BGA series products

Product features

1.Precise fast detection speed;

2.Intelligent high digital CCD camera,the image quality is stable and reliable;

3.Easy.Flexible.Quick programming and debugging;

4.Automatic recognition and A/B surface MARK;

5.Camera barcode identification system;

6.CAD data import automatic search component libraries;

7.Automatic positioning system,greatly improving programming speed;

8.Muti_function SPC statistical system;

Functional Specifications

| Applicable process | After SMT solder paste printing, OR (wave soldering) before and after reflow soldering |

|

Test method |

color image learning, statistical analysis, automatic character recognition (OCR), color distance analysis, IC bridging analysis, black and white ratio analysis, brightness analysis, similarity analysis |

| Image pickup system | Color 3CCD intelligent digital camera |

| Resolution | 20μm,15μm,10μm |

| Illuminating system | Circular tower shaped high brightness three color LED lighting |

| Programming method | Quick manual programming, automatic retrieval of CAD coordinates for component library import |

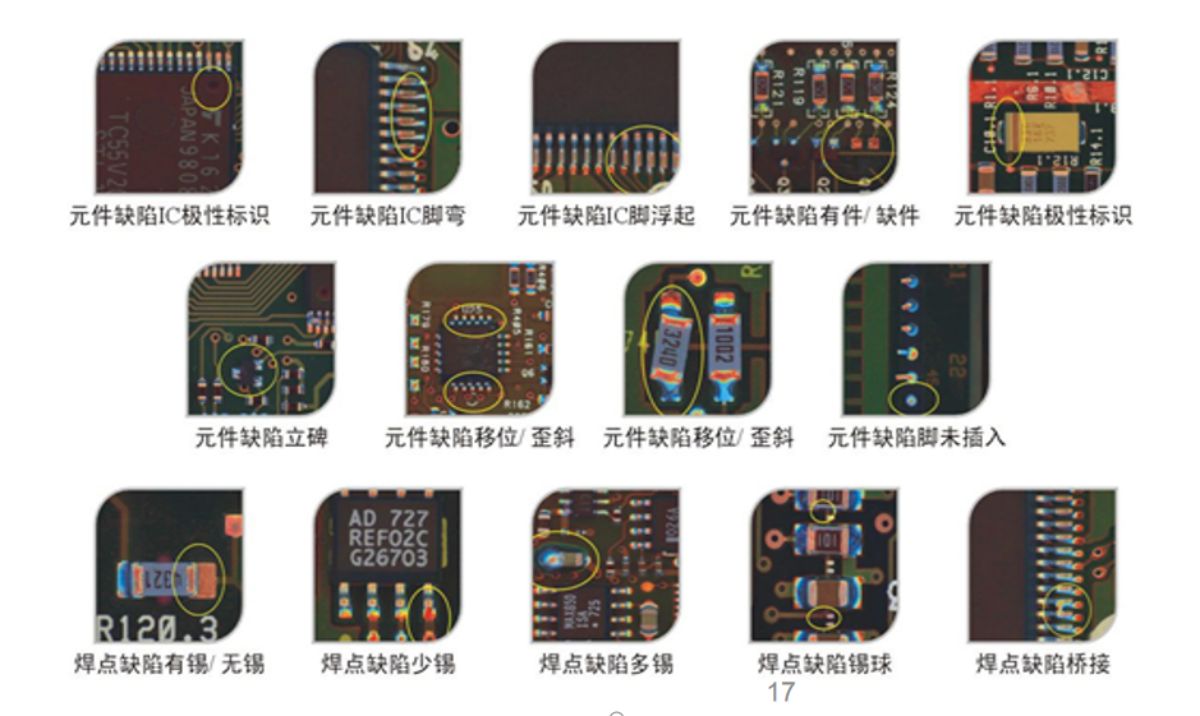

| Inspection Items | Solder Paste Printing: Yes, No, Skew, Less Tin, More Tin, Short Circuit, Pollution;Solder joint inspection: excessive or insufficient tin, tin connection, tin beads, copper foil contamination, wave soldering plug-in solder joint inspection |

| Minimum component test | 01005chip,0.25pitchICOR (0603chip,0.5pitchIC) |

| SPC statistical system | Record test data for statistical analysis, view production quality in Excel output format |

| Barcode system | Camera automatic recognition |

| Operating system | Windows XP,Windows 7 |

| Remote control | Using network remote operation for easy and fast program modification and troubleshooting |

| Test results | Display the specific position of NG through a 22 inch LCD display |

Mechanical system parameters

| PCB size | 25×25mm~500×400mm |

| PCB thickness | 0.3~6mm |

| PCB bending | <3mm |

| PCB Height | Above≤40mm,Below≤100mm |

| PCB Fixed way | Compaction and open automatic fixtures |

| X/Y drive system | AC servo motor drive and screw |

| Positioning accuracy | <10μm |

| Power Supply | AC 22OV±10% 50/60Hz 1KW |

| Environment temperature | 10~40℃ |

| Environment humidity | 10~80%RH |

| Weight | 500KG |

| Dimension | 1100×935×1380mm |

Write your message here and send it to us