Chips? MEMS devices? LEDs? Or something else?

Aluminum Copper Wire Bonder Ultrasonic Wire Bonding Machine for MOS Leading Frame

New energy power batteries, photovoltaic inverters, automotive electronics, energy storage, IGBT, BMS battery safety control boards, etc

Product Specification

| XY Motion Range | 100mm (X) × 100mm (Y) |

| XY Motion Accuracy | Linear Motor, 0.1μm resolution |

| Ultrasonic Bonding | ±0.02mm (includes image/wire/capillary/application alignment) |

| Repeatability & Power | 180‒240V, AC single-phase, 50/60Hz,4.0kVA |

| Equipment Dimensions | 1820mm × 1260mm × 1700mm |

| Z-Axis Travel & Accuracy | Voice Coil Motor, 50mm travel (Z-axis), 0.1μm resolution |

| R-Axis | Torque Motor Drive, ±220°, 0.1μm resolution |

| Control System | Industrial PC + servo drive |

| Compressed Air Pressure/Optional | 0.5‒0.7MPa, clean dry air |

| Weight | 1200kg |

Bonding Wire Materials

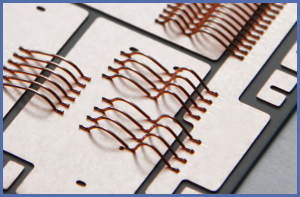

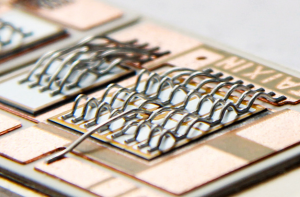

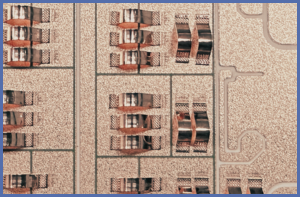

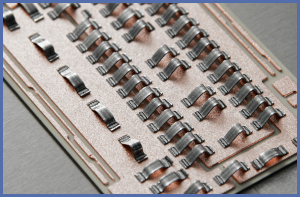

GR-W02 Heavy Wire Bonder is specifically designed for large-diameter wire bonding in IGBTs, intelligent power modules, and hybrid assemblies, delivering a stable and reliable professional solution.

What do you need to bond?

MOSFET packages (TO220, TO220F, TO247, TO252, TO263, etc.) in single-row or multi-row configurations, DBC-based IGBT modules,and other power semiconductor devices.

Write your message here and send it to us