Application of SMT back-end cell line in the 3C electronics industry

GREEN is a National High-Tech Enterprise dedicated to R&D and manufacturing of automated electronics assembly and semiconductor packaging & testing equipment.

Serving industry leaders such as BYD, Foxconn, TDK, SMIC,Canadian Solar, Midea, and 20+ other Fortune Global 500 enterprises. Your trusted partner for advanced manufacturing solutions.

Surface Mount Technology (SMT) is the core process in modern electronics manufacturing, especially for the 3C industry (computer, communication, consumer electronics). It mounts leadless/short-lead components (SMDs) directly onto PCB surfaces, enabling high-density, miniaturized, lightweight, high-reliability, and high-efficiency production.How SMT lines are applied in the 3C electronics industry, and the key equipment and process stages in SMT back-end cell line.

□ 3C electronic products (such as smartphones, tablets, laptops, smartwatches, headphones, routers, etc.) demand extreme miniaturization, slim profiles, high performance,and rapid

iteration.SMT lines serve as the central manufacturing platform that precisely addresses these demands.

□ Achieving Extreme Miniaturization and Lightweighting:

SMT enables the dense arrangement of micro-components (e.g., 0201, 01005, or smaller resistors/capacitors; fine-pitch BGA/CSP chips) on PCBs, significantly reducingcircuit board

footprint, overall device volume, and weight—a critical enabler for portable devices like smartphones.

□ Enabling High-Density Interconnect & High Performance:

Modern 3C products demand complex functionalities, requiring high-density interconnect (HDI) PCBs and multilayer intricate routing. SMT’s precision placement capabilities form the

foundation for reliable connections of high-density wiring and advanced chips (e.g., processors, memory modules, RF units), ensuring optimal product performance.

□ Boosting Production Efficiency & Reducing Costs:

SMT lines deliver high automation (printing, placement, reflow, inspection), ultra-fast throughput (e.g., placement rates exceeding 100,000 CPH), and minimal manual intervention. This

ensures exceptional consistency, high yield rates, and significantly lowers per-unit costs in mass production—perfectly aligning with 3C products’demands for rapid time-to-market and

competitive pricing.

□ Ensuring Product Reliability & Quality:

Advanced SMT processes—including precision printing, high-accuracy placement, controlled reflow profiling, and rigorous inline inspection—guarantee solder joint consistency and

reliability. This significantly reduces defects such as cold joints, bridging, and component misalignment, meeting 3C products' stringent operational stability requirements in harsh

environments (e.g., vibration, thermal cycling).

□ Adapting to Rapid Product Iteration:

The integration of Flexible Manufacturing System (FMS) principles enables SMT lines to rapidly changeover between product models, dynamically responding to the fast-evolving

demands of the 3C market.

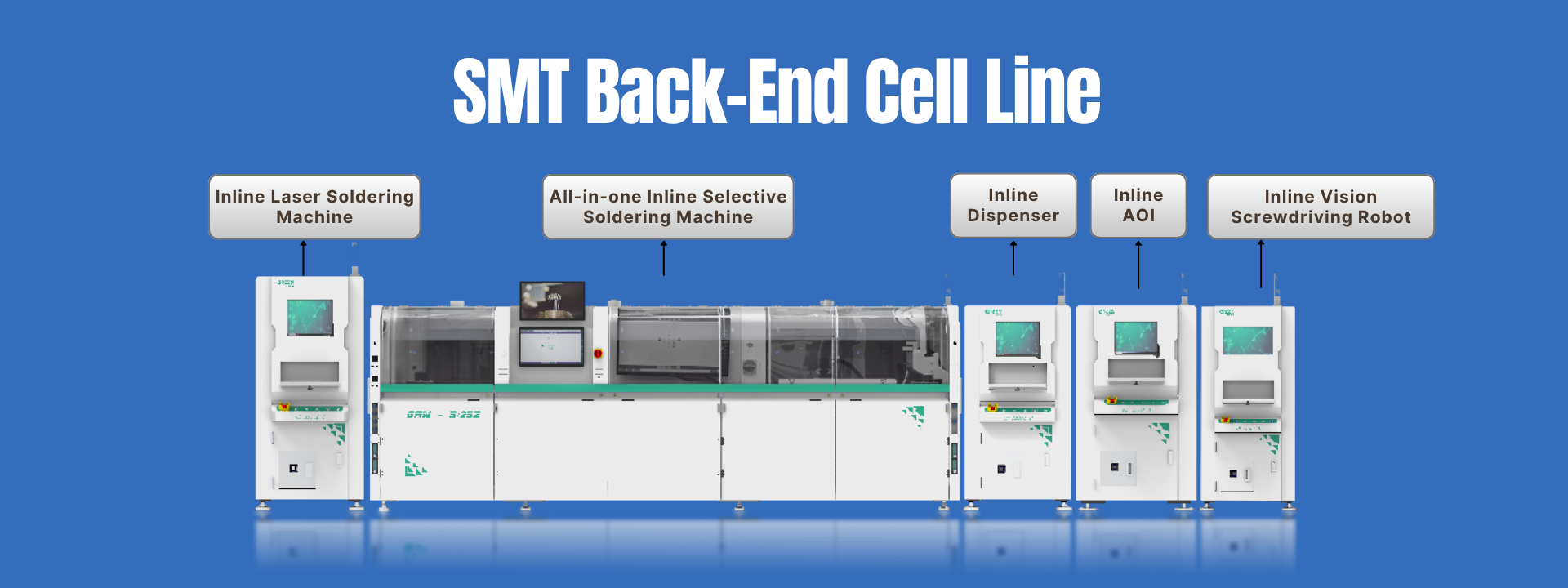

Laser Soldering

Enables precision temperature-controlled soldering to prevent damage to thermosensitive components. Utilizes non-contact processing that eliminates mechanical stress, avoiding component displacement or PCB deformation—optimized for curved/irregular surfaces.

Selective Wave Soldering

Populated PCBs enter the reflow oven, where a precisely controlled temperature profile (preheating, soaking, reflow, cooling) melts the solder paste. This enables wetting of pads and component leads, forming reliable metallurgical bonds (solder joints), followed by solidification upon cooling. Temperature curve management is paramount for weld quality and long-term reliability.

Full-Automatic High-Speed In-Line Dispensing

Populated PCBs enter the reflow oven, where a precisely controlled temperature profile (preheating, soaking, reflow, cooling) melts the solder paste. This enables wetting of pads and component leads, forming reliable metallurgical bonds (solder joints), followed by solidification upon cooling. Temperature curve management is paramount for weld quality and long-term reliability.

AOI Machine

Post-Reflow AOI Inspection:

After reflow soldering, AOI (Automated Optical Inspection) systems utilize high-resolution cameras and image-processing software to automatically examine solder joint quality on PCBs.

This includes detecting defects such as:Solder Defects: Insufficient/excessive solder, cold joints, bridging.Component Defects: Misalignment, missing components, wrong parts, reversed polarity, tombstoning .

As a critical quality control node in SMT lines, AOI ensures manufacturing integrity.

Vision-Guided Inline Screwing Machine

Within SMT (Surface Mount Technology) lines, this system operates as a post-assembly equipment, securing large components or structural elements on PCBs—such as heat sinks, connectors, housing brackets, etc. It features automated feeding and precision torque control, while detecting defects including missed screws, cross-threaded fasteners, and stripped threads.